Fire Protection.

| 1. Interpretation of terms. | 24. | Disposition and minimum number of exit-ways. |

| 2.Fire-resistance rating. | 25 | Required width of Passageways. |

| 3.Assessment of height of buildings or occupancy-units. | 26 | Population once served by an exit-way or exit-ways. |

| CLASSIFICATION OF OCCUPANCY-UNITS NICID-CONSEQUENTIAL STRUCTUAAL REMQUIREMENTS. | 27 | Passageways and ramps. |

| 4. Classification of occupancy-units into classes and grades | 28 | Stairways |

| 5. Separation of occupancy-units and tenancy-units. | 29 | Lobbies, foyers and vestibules, forming part of an exit-way. |

| 6. Maximum cubic capacity of divisions. | 30 | Doorways and doors forming part of exit ways. |

| 7. Particular requirements for grade A construction. | 31 | Exit-courts. |

| 8. Particular requirements for grade B construction. | 32 | Exit-signs and lighting of exit-ways. |

| 9. Particular requirements for grade C construction | 33 | Protection of exit-ways against fire |

| SPECIAL REQUIREMENTS FOR CERTAIN BUILDINGS AND PORTIONS THEREOF | ||

| 10. Particular requirements for grade D construction. | 34 | Places of indoor assembly. |

| GENERAL REQUIREMENTS FOR ALL BUILDINGS II. | 35 | Places of outdoor assembly: provision of seat-ing in grandstandS and similar structures. |

| 11. Fire-resistance rating of supporting structural members. | 36 | Stages and back-stage areas. |

| 12. Division-walls and division. | 37 | Projection and rewinding enclosures. |

| 13. Occupancy-separation structures and tenancy-separation structures. | 38 | Rooms for storage or keeping of film. |

| 14. Openings in external walls. | 40 | Spray-rooms. |

| 15. Service-shafts. | 41 | Rooms containing heating appliances and air-conditioning appliances. |

| 16. Roof-lights and floor-lights. | 42 | Flues, chimneys and smokestacks. |

| 17. Access to roof-spaces. | 43 | Parking-garages |

| 18. Service-pipes set in structural members. | 44 | Storage or keeping of flammable liquids and substances. |

| 19. Fire-stopping. | 45 | Windowless buildings. |

| 20. Access for rescue and fire-fighting purposes. | 46 | Special floors in operating-theatres and similar places. |

| 21. Fire-alarms. | 47 | Ventilation installations and rooms having hazardous dusts and vapors. |

| EXIT-WAYS 22. | 48 | Notices in occupancy-units having a high fire load. |

| FIRE-EXTINGUISHING EQUIPMENT | ||

| 22. Administrative requirements for exit-ways | 49 | Administrative requirements for fire extinguishing equipment. |

| 23. Individual exit-ways. | 50 | Type and disposition of fire-extinguishing equipment. |

| 51 | Hand fire-extinguishers. | |

| 52 | Fitted hose-reels. | |

| 53 | Landing: valves | |

| 54 | Sprinklers. | |

| PART VI WATER-SUPPLY FORCES FIRE-FIGHTING SERVICES. | ||

| 55 | Special conditions | |

| 56 | Connection from communication-pipes. | |

| 57 | Valves in communication-pipes. | |

| 58 | Installation of reflux-valve. | |

| 59 | Extension of system to other premises. | |

| 60 | Details of connection. | |

| 61. | Local authorities which are currently without fire-fighting services. |

FIRST SCHEDULE: Fire-resistance (tests’) of structures. SECOND SCHEDULE: Presumed fire-resistance ( ratings of building-components. THIRD SCHEDULE: Surface spread of flame (test.; FOURTH SCHEDULE: Combustibility test ‘for building materials.

1.INTEPRETATION OF TERMS.

Note.—Before any building proposal is checked against the provisions of this Chapter, it is suggested that clarity is obtained on the to which the various portions of the building will or may be put, for this will determine both its classifications in terms of section 4 it’s into 1 or more of classes (1-11) and grades A to D and its designated fire load low moderate or high in terms of subsection (1) of this section.

(1) In this Chapter—

“arcade” means a pedestrian passage at street-level, of not less than 6 meters in width, which passes through a building or between buildings from one street to another, and which is permanently open at both ends;

“automatic“, as applied to fire-doors, fire-shutters, fire-alarms and fire-extinguishing equipment, means that these are fitted with a device which, without any manual operation, causes the performance of the required function;

“automatic fire-alarm system” means a system which—(a) automatically detects the outbreak of fire in the occupancy-unit it serves; and (b) actuates a fire-alarm signal or device;

“business, commercial or industrial occupancy” means the occupancy for the transaction of business, the rendering of professional services or the display, sale, packing, manufacturing or processing of goods, materials, food or drink, or for the purpose of manual, clerical or other work, and, without derogation from the (ii) by the insertion of the following definitions—”

“fire shutter” means a shutter which—(a) gives a specific, fire-resistant; and (b) closes automatically in the event of Pre;

“roof assembly‘ means the roof structure and any ceiling attached to such structure, but does not include the roof cover,

“suspended or false ceilings” means a ceiling suspended from a floor construction by means of a suspension system, the com-ponents of which shall be deemed to form part of such suspended. Or false ceiling, but shall not include a ceiling forming part of a roof assembly.

portion of a building separated from the remainder of the building by—

(a) one or more division-walls; or

(b) one or more division-floors; or

(c) a combination of such walls and floors;

“division-floor” means a floor which— •

(a) serves to divide a division of a building horizontally from the remainder of the building; and

“division- wall/means a wall which—

(a) serves to divido u division of a building vertically from The remainder of a building, or which is to be erected on a lateral boundary other than—. oy a wall on a lateral boundary separating a dwelling unit; or

(ii) a boundary wall not forming part of a building; or

(iii) the wall of a domestic garage or workers quarters situated on a lateral boundary of a residential

staid; and •

(b) has a required fire-resistance rating;

“exit-way” means a series of components designed to form a route to egress or escape from any storey of a building and is so constructed to resist the entry of smoke or flame for a specified period;

“fire-door” means a door and its assembly which—ta) in the ease of a fire-door installed to contain a fire within a division of a building’ shall— ‘

(i) not be a- component of an exit-way; and

(ii) be specially constructed in accordance with CAS 176 Parts 1 and 2 BCD class doors to give a specific fire-resistance.

(iii) close automatically in the event of fire.

Section 1

generality of the foregoing, includes occu-pancies for—bakeries; laboratories; power-plants; banks; laundries; radio stations; electric substations; markets; shops; factories; offices; telephone exchanges; hairdressing saloons; workshops; but shall not include a place of assembly;

“chimney” means a masonry or concrete shaft enclosing one or more flues;

“combustible”, as applied to material, means material which is classified as combustible when tested, as described in the combustibility • test set out in the Fourth Schedule; •

“division”, as applied to a building, means a portion of a building separated from the remainder of the building by—

(a) one or more division-walls; or

(b) one or more division-floors; or

(c) a combination of such walls and floors;

“division-floor” means a floor which—

(a) serves to divide a division of a building horizontally from the remainder of the building; and

(b) has a required fire-resistance rating; 2 ).”division-wall” means a wall which—•

(a) serves to divide a division of a building vertically from the remainder of the building; and

(b) has a required fire-resistance rating;

“dwelling-house” means a dwelling designed for occupation by a single family or household, and includes a semi-detached dwelling or a dwelling in a terrace of houses and any building appurtenant thereto, but does not include a dwelling-unit;

“dwelling-unit” means a flat or maisonette or other similar portion of a building designed for occupation by a single family or household for living purposes;

“exit” means the point of egress from an exit-way to a public street or arcade or to a public place, whether this be an exit doorway or the mouth of an exit-court;

“exit-court” means an open space, unoccupied from the ground upwards, on the same stand as that on which the building such court serves is erected, and which is bounded by walls or boundaries, or by both walls and stand boundaries, which is a component of an exit-way;

“exit-wall ” means a series of components forming roue of egress or escape from any room in a building, as described in section 23; ,

“fire-door” or

“fire-shutter” means a door or suer and its assembly especially constructed and assembled in place so as to give a specific fire-resistance rating;

“fire-load,” means the degree of fire hazard produced by the contents of an occupancy-unit, characterized as “low”, “moderate” or “high”‘;

“low fire-load” means the fire-load for all occupancy-units, the combustible content of which, together with normal furniture and fixtures, does not at any time exceed 5 per centum by volume of the occupancy-unit concerned:

Provided that factories or shops process- ing, utilizing or storing at least 90 per centum of non-combustible materials, such as hard- ware-shops, bicycle-shops and concrete-block factories, shall be deemed to be occupancy- units having a low fire-load;

“moderate fire-load” means the fire-load for occupancy-units other than high fire-load-or low fire-load;

“high fire-load” means the fire-load for occu- pancy-units, the occupation and use of which involves-

(a) the storage, keeping, manufacture, pack- aging, processing, use or sale of goods or materials-

(i) which are liable to burn with extreme. rapidity; or

(ii) from which poisonous fumes or explosions may be expected, in the event of the outbreak of fire;

ог

(b) uses or processes which result in small particles of combustible material being suspended in the air, so as to be liable to result in an explosion; or

(c) the storage of combustible materials or materials in combustible containers in such a way that conditions for the rapid spread of fire are created, such as the stacking of such containers to a height exceeding 4,5 meters, or in stacks with small gaps between them;

“fire-resistance rating” means the minimum length of time for which a structural element. or a separating structure will resist fire, based. on the stapdard fire test set out in the First Schedule;

“fire-stopping” means a method of preventing the spread of fire within walls and partitions and between floors and ceilings, and in other concealed spaces in a building, by the insertion of a non-combustible filling in voids and concealed spaces so as to restrict the passage of air;

“fire-valve” means a valve fitted to fuel lines which operates automatically in the event of the outbreak of fire shutting off the supply of fuel to the appliance;

“fire-window” means a window and its assembly specially constructed and assembled in place so

as to give protection against the passage of fire;

“flammable“, as applied to solid substances, means those which are likely to cause fire through friction, absorption of moisture or exposure to air or to heat at temperatures below 65 degrees Celsius; as applied to liquids, means those which give off vapors which are explosive when mixed with air or which burn

with estrone rapidity, and those which have a closed-cap (Abd-Perky) flashpoint below 65 degrees Celsius:

“Blue” means a passageway for the purpose of removing products of combustion from solid, liquid or ps fuel:

“Tel-feed incinerator” means an incinerator which is supplied with fuel to maintain com- bustion of the contents, is distinct from an incinerator in which the material being in- cinerated themselves constitute the only fuel promoting combustion;

“garage” means a building or portion of a building used to stove, keep, house or repair one or more motor vehicles powered by internal combustion engines;

“Industrial high-heat appliances me those appliances developing temperatures in the heated materials or ovens exceeding 800 degree Celsius, including, among others, espolas, beas-furnaces, porcelain-baking kilma and Bessemer retorts:

“industrial low-heat appliances” mess these appliances developing temperatures in the hated materials or ovens not ending 300 degrees Celsius, including, among others, cooking-ranges, small hot-water boilers, wood- drying furnaces, bake-ovans in bakeries, coffee rosting ovens and bolling-vats for wood-fibre;

“industrial medium-heat appliances” means those appliances developing temperatures in the heated materials or ovens esling 300 degrees Celsius, but not exceeding 300 degrees Celsius, including, among others, high-preisse stewm-bailers, charcoal-Carnaces, lime-kilos and ferlize-driers heated by direct fire;

“Institutional occupancy” means the occupancy in which persons receive medical, charitable or other care or treatment, or in which persons are involuntarily detained, and, without derogation from the penalty of the foregoing. includes occupancies for

| creches | maternity homes | nursing homes |

| homes for the aged | mental hospitals | orphanages |

| hospitals | nursaries | sanatoria |

| infirmaries |

bat shall not include a place of assembly;

“lateral boundary“, in relation to a building, means a boundary of the stand on which such building is erected, other than a boundary between sech stand and a public street or public place, where such public sector public place is more than 4,5 metres in width;

“scary” means an assembly of non-com- balle structural-units of reisral stone, cast stone, brick or concrete, or similar building- units bonded together;

“aca-combustible“, as applied to material, masa material which is not combustible;

“occupancy“” means the use or purpose to which a building or portion of a building is normally put or is intended to be pat, according to whether the use or purpose is

(a) business, commercial or industrial; or

(b) institutional; or

(c) public and assembly; or

bars,

(d) residential; or (e) storage:

“occupancy-separation structure” means a wall, Beor or other structure which separates ons occupancy-unit from another;

“occupancy-unit” means a building or portion of a building used for a particular occupancy: “partition-wall” means a non-bearing lateral wall which is employed solely for the purpose of subdividing any storey of a building into

sections:

“petrol-filing station” means a building or any part thereof, where a fammable Buid for direct supply to motor vehicles is kept, stored or sold; “place of assembly” means a room or space in a building accommodating 100 or more persons, and includes any other room or space, whether on the same storey or another storey of the building, which is connected to, or has a common entrance with, the room or space socommodating 100 or more persons; “population”, in relation to an occupancy-unit, means the population determined in accordance with the provisions of section 25;

“public occupancy” and “assembly occupancy” mean the occupancy in which persons regalarly gather together for civic, political, educational, religious, cultural, social or recreational purposes, whether such gathering be of a public, restricted or private nature and, without derogation from the generality of the foregoing. includes occupancy for-

| arenas | colleges | museums |

| armouries | concert-halls | opera house |

| bars | dance halls | passenger stations |

| bath house | dinning rooms | places of assembly |

| bowling alleys | exhibition buildings | places of worship |

| cafes | galleries | restaurants |

| canteens | grandstands | schools (non-residential) |

| cinemas | gymnasia | skating rinks |

| circuses | lecture rooms. | stadia |

| classrooms. | libraries | theatres |

| clinics | lounges | |

| club rooms. | mess rooms. |

“required” means required by the provisions of this Chapter:

“residential occupancy means the occupancy. other than an institutional occupancy of place of assembly, in which people sleep, and, without derogation from the generality of the foregoing, includes occupancies for

| boarding house | dwellings | marionettes |

| colleges (residential) | hostels | monasteries |

| convents | hotels | motels |

| dormitories | lodging houses | residential club’s schools (residential) |

“self-closing”, as applied to fire-doors, fire- shutters and fire-windows, means a free-door, fire-shutter or fire-window which is normally held in a closed position by some mechanical device and automatically returns to a closed position whenever it is released after being opened;

“shaft” means a vertical opening or passage completely or partly enclosed by wall, which passes through two or more floors of a building or through doors and roof;

“smoke-pipe” moss a pipe connecting a heating appliance and a fue;

“smoke-stack” means a shaft of material other than masonry or concrete enclosing one or more fus

“sprinkler” means an automation sprinkler;

“stairway” mean one or more flights of stairs and the landings appurtenant thereto forming a continous and uninterrupted passage from one storey to another in a building

“storage occupancy” means the occupancy for the storage or keeping of goods, wares or merchandise, the sheltering of livestock, or the housing of aero planes and other means of transport, tad, without derogation from the generality of the foregoing, includes occupancies for

| barns | goods depots | petrol filling stations |

| cold stores | grain elevators | stables |

| garages | hangars | storage warehouses |

| infirmaries |

Provided that any store-rooms or space wh () in the opinios of the local authority is ancillary to an occupancy other than a storage occupancy; and

(b) does not exceed 60 cubic meters in capacity; and

(c) not used for the storage or keeping of flammable substances

may be deemed to be used for the occupancy to which, in terms of paragraph (a),

ancillary

ancy-separation structure” means a wall, floor or other structure which separates one portion of an occupancy-unit from another portion of the same occupancy-unit used by a different lesant or owner

“tip-up seat” means a sest which tips up automatically by a mechanism actuated by weights, springs or other approved mas

“well-lining” means a material exceeding 1 millimeter in thickness applied to a wall subsequently to the constriction of the wall.

(2) In estimating the degree of fire hazard for the purpose of assessing the fire-hood of an occupancy unit, the estimate shall be based on the assumption that the contents of the unit are uniformly distributed over the total floor area of the unit.

(3) Goods or materials, such as varnishes, cotton, feathers, flour, fireworks, straw, laceme, kapok, oil based paints, rubber, certain plastics and similar goods or materials which are not classed as dam mable, shall be deemed to fall within the scope of the materials referred to in paragraph (a) of the definition of

“high fee-load”.

2. FIRE RESISTANCE RATING.

(1) Where a particular fire-resistance rating is required by the provision of this Chapter for a component or an assembly of components of a building, such requirement shall be deemed to have been fulfilled, if the component or assembly of components—

a) Has been proved b a test conducted in accordance with the First Schedule to have the required fire-resistance rating; or

b) Is constructed in accordance with the appropriate requirements for the fire-resistance ratings set out in the Second Schedule; or

c) Has been assessed by an approved independent organization to have the required fire-resistance rating.

(2) The provisions of paragraph (b) of sub-section (1) shall not apply to a fire-door, as described in Table IX of the Second Schedule, unless there is fixed to such door a metal plate, bearing—

a) The name of the manufacturer of such door; and

b) The date of manufacture of such door; and

c) A certificate in the following form—

“this door is constructed to comply with the requirements prescribed by the building By-laws for a door having a fire-resistance of…………………………..………………. hours.”

(3) Fire-doors which otherwise comply with the requirements of Table IX of the Second Schedule for doors having a presumed fire-resistance rating of half an hour, shall retain such rating although one or more openings are provided therein, if such openings are glazed with fire-resisting glazing, in accordance with the specifications set out in the Second Schedule.

3. ASSESSMENT OF HEIGHT OF BUILDINGS OR OCCUPANCY -UNITS.

(1) Where the height of a building or occupancy-unit is given in storeys, as set out in this Chapter, the number of storeys shall be regarded as those contained between the floor nearest the finished ground-level, at the point considered, and the roof of such building or the top of such occupancy-unit.

(2) A mezzanine floor having an aggregate floor area exceeding 20 per centum of the floor area of the storey in which it is located shall be regarded as a separate storey.

(3) Where the height of a building or an occupancy-unit is given in metres, as set out in this Chapter, the height shall be regarded as the vertical distance between the unfinished ground-level, at the point considered of such building or occupancy-unit, and the underside of a flat-roof construction or a point half-way up the roof-pitch in a sloping-roof construction.

(4) Where structures which are erected on the roof of a building or an occupancy-unit contain habitable rooms, used as part of the occupancy of such building or occupancy-unit, the height shall be the vertical distance between the ground-level, at the point considered adjoining such building or occupancy-unit, and the underside of the ceilings of such rooms.

4. CLASSIFICATION OF OCCUPANCY -UNITS INTO CLASSES AND GRADES.

(1) Every occupancy-unit shall—

a) Be classified into one of the classes and grades of construction specified in this section; and

b) Be erected in accordance with the section of these by-laws in which the structural requirements appropriate to the relevant grade are specified.

(2) Grade A construction. – Every occupancy-unit which falls into one or other of the following five classes shall be erected in accordance with the requirements specified in this Chapter for grade A construction—

Class 1. —Institutional occupancy-units in which persons are involuntarily detained or in which persons, who by reason of infirmity are unable to help themselves, are housed, of one or more storeys height;

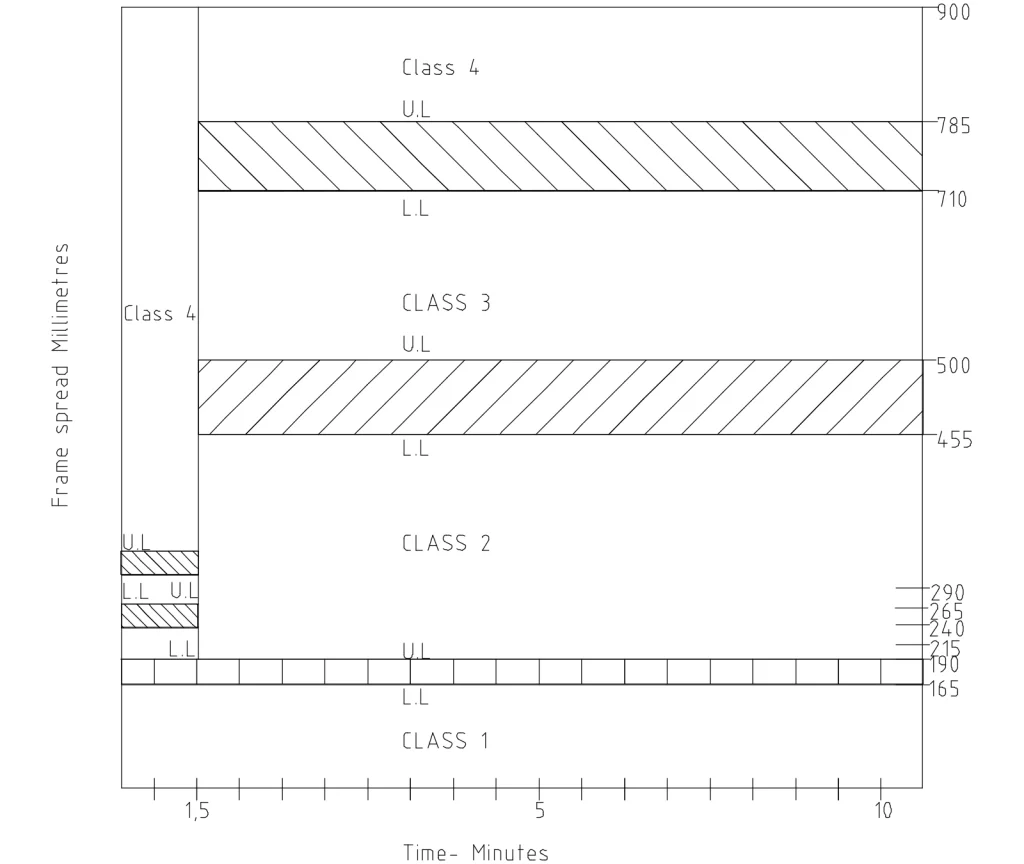

Class 2. —Theatres, cinemas and opera-houses of one or more storeys in height, and occupancy-units containing a place of assembly above the ground storey;

Class 3.—Institutional and public and assembly occupancy-units, other than those in classes 1 and 2, of three or more storeys or over 10,5 metres in height, places of worship over 13,5 metres in height, and schools and colleges, whether residential or otherwise, exceeding two storeys in height;

Class 4.—Business, commercial or industrial occupancy and residential occupancy-units of five or more storeys or over 15 metres in height;

Class 5.—Storage occupancy-units of two or more storeys or over 10,5 metres in height, but excluding units for the storage of flammable liquids and substances, as provided for in section 44.

(3) Grade B construction. —Every occupancy-unit which falls into one or other of the following three classes shall be erected in accordance with the requirements specified in this Chapter for grade B construction—

Class 6. —Institutional and public and assembly occupancy-units, other than those in classes 1 and 2, not exceeding two storeys or 10,5 metres in height, and places of worship 13,5 metres

Class 7. —Business, commercial or industrial occupancy-units and residential occupancy-units not exceeding four storeys or 15 metres in height, but exceeding, in the case of dwelling-houses, two storeys in height, and, in the case of all other residential occupancy-units and all business, commercial or industrial occupancies, exceeding one storey in height;

Class 8. –Storage occupancy-units not exceeding one storey or 10,5 metres in height, but exceeding 6 metres in height, but excluding units for the storage of flammable liquids and substances, as provided for in section 44.

(4) Grade C construction. – Every occupancy-unit which falls into one or other of the following two classes shall be erected in accordance with the requirements specified in this Chapter for grade C construction–

Class 9. –Business, commercial or industrial occupancy-units not exceeding one storey in height;

Class 10. –Storage occupancy-units not exceeding one storey or 6 metres in height or 7 000 cubic metres in capacity, but excluding units for the storage of flammable liquids and substances, as provided for in section 44.

(5) Grade D construction. – Every occupancy-unit which falls into the following class shall be erected in accordance with the requirements specified in this chapter for grade D construction—

Class 11. – Dwelling-houses not exceeding two storeys in height.

(6) Nothing contained in this section shall be constructed as prohibiting the erection of a particular occupancy-unit which complies with the requirements of a higher grade of construction than that under which such occupancy-unit falls in terms of this section, and, if a unit is so constructed, the cubic capacity of such occupancy-unit may be increased to that applicable to such higher grade of construction, as set out in section 6.

(7) Where there is any doubt or dispute as to the grade of construction or the fire-load category into which an occupancy-unit falls, the decision of the local authority shall be final.

5.SEPARATION OF OCCUPANCY-UNITS AND TENANCY-UNITS.

(1) Except as provided in subsection (3), every occupancy-unit and every portion of an occupancy-unit occupied by a separate tenant shall be separated by means of an occupancy-separation structure or a tenancy-separation structure, as the case may be, complying with section 13, from any adjoining occupancy-unit or portion thereof, as the case may be.

(2) Except as provided in subsection (3), where there are several occupancy-units in a building, all of which do not have the same occupancy, each such occupancy-unit shall comply with the requirements of this Chapter applicable to it.

(3) The provision of occupancy-separation structures between different occupancy-units comprised in one building, as set out in subsection (1), may be omitted between such occupancy-units as are in one tenancy, if all such occupancy-units comply with the requirements of this Chapter which are applicable to that occupancy-unit included in them which requires the most stringent precautions.

6. MAXIMUM CUBIC CAPACITY OF DIVISIONS.

(1) All buildings with a capacity greater than is permitted for a division under Table I shall be subdivided into divisions, and no such division shall have a greater cubic capacity than is permitted in that Table.

(2) Such cubic capacity may be measured exclusive of the thickness of the containing walls or floor-slabs, and exclusive also of the whole roof construction, including the ceiling, where this construction is constructed if non-combustible material.

(3) Where of the roof construction, including the ceiling, is constructed of combustible material, the volume, of the whole roof construction shall be included in assessing the volume of the division.

(4) The cubic capacities specified in column 3 of Table I for single-storey buildings without basements, or divisions without basements, may be doubled in the case of buildings or divisions provided with an approved sprinkler system throughout the building or division, or with the approval of the local authority an alternative automatic extinguishing system, and, in the case of buildings or divisions of grade A construction, having low or moderate fire-load, which are so provided, such capacity may be unlimited.

(5) The cubic capacities specified in column 4 of Table I for multi-storey buildings may be increased at the discretion of the local authority, under such conditions as the local authority may prescribe, in the case of buildings or divisions provided with an approved sprinkler system throughout the building or division, or with the approval of the local authority an alternative automatic extinguishing system.

(6) Notwithstanding the particular requirements of section 8 and 9, it shall be permissible to use unprotected steel columns and beams in any single-storey building or division of a building referred to in subsection (1) which is wholly used for any of the following occupancies—

a) Business, commercial or industrial occupancy of low or moderate fire-load;

b) Storage occupancy, having a low or moderate fire-load;

c) Public and assembly occupancy in which—

i) Category A, mentioned in column 5 of Table I, shall include occupancies for theatres, cinema, cafes and exhibition-buildings; and

ii) Category B, mentioned in column 5 of Table I, shall include class-rooms, club-rooms, clinics and places of worship;

Both categories having a population not exceeding 300.

(7) In Table I, construction referred to in sub-section (6) is termed “unprotected steelwork construction”, and all other construction is termed “fire-protected construction”.

TABLE I

MAXIMUM CUBIC CAPACITIES OF BUILDINGS OR DIVSIONS

| 1 | 2 | 3 | 4 | 5 |

| Max cubic capacity of building or division in cubic meters for | ||||

| Occupancy and fire load of building | fire protected construction. | unprotected steelwork construction | ||

| Construction grade | Single storey without basement | Multi storey | Single storey without basement | |

| Residential institutional public and assembly, business commercial or industrial all of low fire-load | A | 42000 | 14 000 | Business, commercial and industrial: 14 000 Public and assembly: 1400 for category A; 4200 for category B |

| B | 21000 | 7000 | ||

| C | 14000 | Not permitted | ||

| Industrial or commercial of moderate fire-load | A | 35000 | 10500 | 7000 |

| B | 14000 | 5250 | ||

| C | 10500 | Not permitted | ||

| Industrial or commercial of high fire-load | A | 28000 | 7 000 | |

| B | 10000 | 2 800 | not permitted | |

| C | 7000 | Not permitted | ||

| Storage with low or moderate fire load | A | 28000 | 7000 | 7000 |

| B | 14000 | 3500 | 7000 | |

| C | 7000 | Not permitted | 7000 | |

| Storage with high fire load (Other than as provided for section 44) | A | 14000 | 4200 | |

| B | 7000 | 2100 | ||

| C | 3500 | Not permitted | Not permitted |

*Unlimited, if approved sprinkler system or approved alternative automatic extinguishing system is installed.

7. PARTICULAR REQUIREMENTS FOR GRADE A CONSTRUCTION.

(I) Grade A construction means construction complying with the particular requirements of this section. (2) Structural members. —Except as otherwise provided in subsection (5), all structural members in buildings shall be of non-combustible materials, and all such members shall have fire-resistance ratings of not less than the ratings specified in Table II.

Fire Resistance Ratings of structural members for grade A construction.

| 1 | 2 | 3 | 4 |

| Fire Resistance Rating In hours. | |||

| Structural Member | Class 1 occupancy units | Low or moderate fire load | High fire load |

| Bearing walls, columns and beams | 2 | 1.5 | 2 |

| Division walls and suspended division walls complying with section 12. Other suspended floors | 4 2 | 4 1.5 | 2 2 |

(3) External nonbearing-walls. –All external non-bearing-walls of a building, which are within the distances from the nearest lateral boundary of the stand on which such building is erected or from another building on such stand, specified in column I of Table III, shall have fire-resistance ratings of not less than the corresponding rating specified in column 2 of that Table.

Fire Resistance Ratings of structural members for grade A construction.

| 1 | 2 |

| Distance of wall from the nearest lateral boundary or another building of the same stand in meters | Minimum fire resistance in hours |

| Less than 1.5 ……………….. 1.5-3……………………………….. over 3 ……………………………. | 1.5 1 0.5 |

(4) Covering to the surface of external walls. — Any, covering to, the exterior surface of external wall shall be of non-combustible ‘Materials: ” ‘ • • • Provided that timber or other combustible material, to an extent not exceeding 20 per centum of the superficial area of openings formed for show-

windows, tray’ be used for such opening, up to the ceiling. Level of the ground Storey or to • height of 6 meters above finished ground-level, whichever is the lower. 15) Suspended flows and flow finMet of (WM &whir metnials.—Su.pciakd floors or floor finishes of timber or other combustible material shall not be permitted, except for—(a) the floor of any stage or platform, if the space beneath such floor vs not used for storage purposes: (b) sprung floors if—(I) such toots are supported out at haw having the appropriate resistance rating for suspended floors, as specified in columns 2, 3 and 4 of Tahoe and (ii) oo portion of such floors s more than 450 millimeters above such base; (c) the finishes or wearing-surfaces of (loon /satanic non-cornbustibte bum, but not in rooms in which flaminabb substances are stored. > (6) Roof asionblies.—Curry fool y in any oceuponepunit whoa f Tails I shall have a fite-renuance ra – not less than one hour, and every oth assembly shall have a fire.resistnnve ipsdavirnot less than half an hour. (7) Combustible material shall not be used as roof-covering, except that, whets the roof conutuo-lion is of concrete or other non-combustible construction, bituminous felt or other approved corn. buttiblc material may be used to cover such construction.

LO ) (I) Roo t 5.— rimy roof-space tuween_. 1 mill a a s opmg roof which woutd_citherivite in pita area. measured at crilum-Itt.cl, the area set out in column 2 of TableiVnliall be suspended by walls acting as dtauglirstops into sechons, each having a plan iv.ft-Sot CI(OtOdIllit the area aforesaid and sue -subdividing.wells shall not be fatting apart distance set out in column 3 of that Table.

Required Subdivision of ceiling roof space for grade A construction.

| 1 | 2 | 3 |

| Occupancy | Maximum plan Area contained. Between subdividing walls acting as draught stops in square meters. | Maximum plan Area contained. Between subdividing walls acting as draught stops in meters. |

| Residential | 180 | 15 |

| Other than Residential | 270 | 30 |

(9Subdividing-walls acting as draught-stops shall be of brick with a crushing strength of at least 10 megapascals and class C mortar, as specified in Chapter 5, and of not less than 100 millimetres in thickness: Provided that, if their length exceeds 10,5 metres or their height above ceiling-level exceeds 1.4 metres, they shall be not less than 215 millimetres in thickness, and be laid in English bond or Flemish bond. (10) Every subdividing-wall shall be taken up to the underside of the roof-covering for the full thick-ness of the wall, and shall comply with the relevant requirements for an occupancy-separation structure, as set out in section 13.

(11) Every roof-space formed by a sloping, pitched or saw-tooth roof which—(a) is not separated from the space immediately below by a ceiling; and (b) would otherwise cover a plan area exceeding 500 square meters; shall be subdivided, by means of approved suspended roof-space partitions of incombustible material having a fire-resistance rating of not less than half an hour, into sections, each of which covers a plan area not exceeding 500 square meters.

(12) The roof-space partitions shall be taken close to the underside of the roof-covering, so as to allow no air passage between partition and roof and shall extend down to the level of the top of the walls or to the bottom of the tie-beams, girders or other roof construction, whichever is the lower.

(13) Approved automatic ventilation-openings shall be provided in every such subdivision of a roof-space, and in every such subdivision formed by the roof construction.

.11-.• (14) Partition-walls. —Every partition-wall shall be of non-combustible material in the following cases—(a) in all basements; (b) in alt Storeys of occupancy-units of class 1; and (c) in all occupancy-units of high fire-load. (15) Every partition-wall in locations other than those specified in subsection (14) shall be of non-combustible material or shall be of timber or other framing covered on both sides with material graded as class 1 in the Third Schedule. (16) Every doorway in partition-walls in basements shall be fitted with a fire-door having a fire-resistance rating of not less than half an hour. (17) Interior trim and finishes. —The use of combustible material for trim to door- and window-frames, and for skirtings and chair- and picture-rails shall be permitted, if such trim and finishes are backed solidly with non-combustible material. (18) Interior wall-linings. —Any interior wall-linings in a class I occupancy-unit shall be of non-combustible materials. 1’4’4(19) Any interior wall-linings in rooms used for sleeping purposes in classes 2, 3 and 4 occupancy-units shall be of material graded as class 1 in the Third Schedule.

windows, may be used for such openings up to the ceiling-level of the ground storey or to a height of 6 metres above finished ground-level, whichever is the lower. (5) Suspended floors and floor finishes of com-bustible materials.—Suspended floors or floor finishes of timber or other combustible material shall not be permitted, except for—(a) the floor of any stage or platform, if the space beneath such floor is not used for storage purposes; (b) sprung floors if—(i) such floors are supported on a base having the appropriate • fire-resistance rating for suspended floors, as specified in columns 2, 3 and 4 of Table II; and (ii) no portion of such floors is more than 450 millimetres above such base; (c) the finishes or wearing-surfaces of floors having non-combustible bases, but not in rooms in which flammable substances are stored.

in “(:), Roof Assemblies.—Every tool asscm- ave Hy in occupancy-unit which falls into occu- Ind piwcy in ;:occupancy classes, I to 3, and residential nee occupancy in occupancy class 4 shall have a fire- -“–1 resistance rating of not less than one hour.”; // 1/44/1111./MLIVIC – – as roof-covering, except that, where the roof construction is of concrete or other non-combustible construction, bituminous felt or other approved combustible material may be used to cover such construction.

44(g) Roof spaces.-Every .roof-space between a ceiling and a sloping roof which would e a f. t T V shall be subdivided into sections by ! the area set out in column 2 o. Table otherwise exceed in plan arca; measured at ‘id walls or approved roof space partitions acting rh, as draught stops, each having a plan area not exceeding the area afore said, and such sub- ) dividing-walls, or • approved partition as the case may be, shall not be further apart than RI the distance set out in column 3 of that Table.

8. Particular Requirements for Grade B Construction.

(1) Grade B construction means construction complying with the particular requirements for this section.

(2) Structural members. – Except as otherwise provided in subsections (3) and (5), all structural members shall have fire-resistance ratings of not less than the ratings specified in Table V.

TABLE V

FIRE_RESISTANCE RATINGS OF STRUCTURAL MEMBERS FOR GRADE B CONSTRUCTION

| 1 | 2 |

| Distance of wall from the nearest lateral boundary or another building of the same stand in meters | Minimum fire resistance in hours |

| Less than 1.5 ……………….. 1.5-3……………………………….. over 3 ……………………………. | 1.5 1 0.5 |

(3) External walls and external members. – External bearing-walls and non-bearing-walls and external members of structural frames of a building, which are within the distances from the nearest lateral boundary of the stand on which such building is erected or from another building on such stand, specified in column 1 of Table VI, shall have fire-resistance ratings of not less than the corresponding rating specified in column 2 of that Table.

TABLE VI

FIRE-RESISTANCE RATINGS OF EXTERNAL WALLS AND EXTERNAL MEMBERS OF STRUCTURAL FRAMES FOR GRADE B CONSTRUCTION

| 1 | 2 |

| Distance of wall from the nearest lateral boundary or another building of the same stand in meters | Minimum fire resistance in hours |

| Less than 1.5 ……………….. 1.5-3……………………………….. over 3 ……………………………. | 1.5 1 0.5 |

(4) Covering to the surface of external walls. –

Any covering to the exterior surface of external walls shall be of non-combustible materials:

Provided that timber or other combustible material, to an extent not exceeding 30 per centum of the superficial area of openings formed for show-windows may be used for such openings up to ceiling-level of the ground storey, or to a height of 6 metres above finished ground-level, whichever is the lesser.

(5) Suspended floors. – Suspended floors of timber or other combustible material shall not be permitted except for—

a) The floor of any stage or platform, if the space beneath such floor is not used for storage purposes;

b) Floors on the ground storey of any building, if no part of the space under such floors is used for other than floor-inspection purposes; and

c) Sprung floors if—

i) Such floors are supported on a base having the appropriated fire-resistance rating for suspended floors, as specified in columns 2 and 3 of Table V; and

ii) No portion of such floors is more than 450 millimetres above such base.

(6) Roof assemblies. —Every roof assembly shall have a fire-resistance rating of not less than half an hour.

(7) Combustible material shall not be used as exterior covering to such roof assembly;

Provided that, where the roof construction is of concrete or other non-combustible construction, bituminous felt or other approved combustible material may be used to cover such roof construction.

(8) Every roof-space in a sloping roof having a ceiling shall comply with the relevant requirements of subsections (8) and (9) of section 7.

(9) Partition-walls. –Every partition-wall in a basement shall be of non-combustible material.

(10) Every partition-wall in a storey above the ground storey in auditoria, bowling-alleys, dancehalls, colleges and schools, both residential and non-residential shall be 0f—

a) Non-combustible materials; or

b) Timber or other framing covered on both sides with a material graded as class 1 in the Third Schedule.

(11) All partition-walls, other than those described in subsections (9) and (10), shall be of—

a) Non-combustible materials; or

b) Timber or other framing covered on both sides with a material graded as class 3 in the Third Schedule.

(12) Every doorway in partitions in basements shall be fitted with a fire-door having a fire-resistance rating of not less than half an hour.

(13) Interior trim and finishes. –The use of combustible material shall be permitted for trim to door and window-frames, and for skirtings and chair- and picture-rails, if such trim and finishes are backed solidly with non-combustible material.

(14) Interior wall-linings. – Any interior wall-linings in rooms used for sleeping purposes shall be of material graded as class 1 in the Third Schedule.

(15) Any interior wall-linings, other than linings applied to walls of required exit-ways and of rooms used for sleeping purpose, may be of combustible material, if such walls are of masonry or concrete.

9.PARTICULAR REQUIREMENTS FOR GRADE C CONSTRUCTION.

(1) Grade C construction means construction complying with the particular requirements of this section.

(2) Structural members. – Except as otherwise provided in subsections (3) and (4), all structural members shall have fire-resistance ratings of not less than the following—

a) occupancy-units with high fire-load, one hour;

b) occupancy-units with moderate fire-load, half an hour; and

c) occupancy-units with low fire-load, no requirement.

(3) External walls and external members of structural frames. – External walls and external members of structural frames of a building which are within the distances from the nearest lateral boundary of the stand on which such building is erected or from another building on such stand, specified in column 1 of Table VII, shall have fire-resistance ratings or fire protection, as the case may be, not less than the appropriate rating or protection specified in column of that Table.

Table VII

Fire-Resistance Ratings And Fire Protection For External Walls And External Members Of Structural Frames For Grade C Construction

| 1 | 2 |

| Distance of wall from lateral boundary or another building on the same stand in metres. | Fire protection requirements |

| Less than 1,5 | 1.5-hour fire resistance rating and to be non -combustible. materials |

| 1,5-3 | 1.-hour fire resistance rating and to be non -combustible. materials |

| More than 3 but less than relevant distance set out in column 2 of table IX | 0.5-hour fire resistance rating and to be non -combustible. materials |

| Not less than the relevant distance set out in column of table IX but less than that set in column 3 of the Table | to be protected externally with approved non-combustible material. |

(4) Where, in consequence of additions, any external wall of an existing building will be at a leaser distance from the nearest lateral boundary or from another building on the same stand than is required for the increased floor area of the ground storey set forth in Table IX resulting from such additions, such wall shall be permitted to remain in its existing position, if every external wall or external structural frame which is a part of such additions is erected in accordance with the requirements set out in Table VIII below.

Table VIII

Requirements Following On Erection Of Certain Additions

| Conditions | Minimum distance of external wall or external structural frame which is a part of the additions from the nearest lateral boundary or another building on the same stand. |

| Where additions to a building increase the floor area of the ground Storey of such building by not more than 100 per centum or increase by not more than 50 per centum the length of any existing external wall or external structural frame of such building, which said wall or frame faces the nearest lateral boundary or faces another building on the same stand. | As required in terms of Table IX for a building of the increased floor area of the ground Storey |

| Where additions to a building increase the floor area of the ground Storey of such building by more than 100 per centum or increase by more than 50 per centum the length of any existing ex-ternal wall or external structural frame of such building, which said wall or frame faces the nearest lateral boundary or faces another building on the same stand. | 600 millimeters more than re-quired, in terms of Table IX, for a building of the increased floor area of the ground Storey |

(5) Subject to the requirements of subsection (7), the distance between any external wall or external structural frame of a building which is of combustible construction and the nearest lateral boundary of the stand on which such building is erected, or between such wall or member and another building on the same stand, shall be not less than that specified in Table IX, in which such walls or frames are placed in the following classes—

Class A- External walls or external structural frames of combustible construction protected externally with approved non-combustible material; and

Class B-External walls or external structural frames of combustible construction not falling into class A.

TABLE IX

BOUNDARY OR SEPARATION DISTANCES FOR EXTERNAL WALLS OR EXTERNAL MEMBERS OF STRUCTURAL FRAMES OF A BUILDING WHICH ARE COMBUSTIBLE—GRADE C CONSTRUCTION

| 1 | 2 | 3 |

| Distance of wall from the nearest lateral boundary or another building of the same stand in meters | Distance to nearest lateral boundary. or another building on the same stand in meters. | |

| Class A | Class b | |

| Up to 1000……………….. 1001- 2000……………………………….. Over 2000 ……………………………. | 3.6 4.2 4.8 | 6.0 7.5 9.0 |

(6) Floors. – All floors shall have a fire-resistance rating of not less than half an hour, and all floors constructed directly over basements shall be of non-combustible materials as a floor finish.

(7) Roof assemblies. – No roof of a building shall be covered with thatch or wooden shingles:

Provided that a building not exceeding 1 400 cubic metres in capacity and having walls of non-combustible materials and a low fire-load may have a roof covered with thatch or wooden shingles if –

a) Such building is not less than 10 metres from any boundary whatsoever of the stand on which such building is to be erected; and

b) Such building complies with the relevant requirements of subsection (8) to (11) of section 10.

(8) The covering of all roofs of buildings having high or moderate fire-load occupancy-units shall be of non-combustible materials:

Provided that, where a roof construction is of concrete or other non-combustible construction, bituminous felt or other approved material may be used to cover such roof construction.

(9) All roof-members in buildings having a high fire-load shall be separated from the room or rooms below such members by a ceiling construction or other protection having a fire-resistance rating of not less than half an hour.

(10) Partition-walls. – Every partition-wall in a basement shall be of non-combustible material, and every doorway in such partition-wall shall be fitted with a fire-door having a fire-resistance rating of not less than half an hour.

10. PARTICULAR REQUIREMENTS FOR GRADE D CONSTRUCTION.

(1) Grade D construction means construction complying with the particular requirements of this section.

(2) Walls and structural frames. – All external walls which have roofs covered with thatch or wooden shingles shall be of non-combustible materials, and except where otherwise provide in subsection (3), all bearing-walls or structural frames shall have a fire-resistance rating of not less than half an hour.

(3) External walls and external members of structural frames. – Non-combustible external bearing-walls and non-bearing-walls and external members of structural frames of a building shall comply with the requirements of subsection (3) of section 9.

(4) Subject to the requirements of subsection (9), the distance between any external wall or structural frame of combustible construction of an occupancy-unit falling under class 11 and another building on the same stand, or between such wall or frame and the nearest lateral boundary of such stand, shall be not less than the distance specified in Table X, in which such walls or frames are placed in the following classes of construction—

Class A. – External walls or external structural frames of combustible construction protected externally with approved non-combustible material; and

Class B. –External walls or external structural frames of combustible construction not falling into class A.

TABLE X

BOUNDARY OR SEPARATION DISTANCES FOR EXTERNAL WALLS OR EXTERNAL MEMBERS OF STRUCTURAL FRAMES OF A BUILDING WHICH ARE COMBUSTIBLE—GRADE D CONSTRUCTION

| 1 | 2 | 3 |

| Distance of wall from the nearest lateral boundary or another building of the same stand in meters | Distance to nearest lateral boundary. or another building on the same stand in meters. | |

| Class A | Class b | |

| Up to 60……………….. 61-150 ……………….. 151-215……………………………….. Over 215 ……………………………. | 2.7 3.6 4.2 4.5 | 5.1 6.7 7.9 8.7 |

(5) Floors. – All floors of rooms constructed in the roof-space of any building having a roof covered with thatch or wooden shingles shall be of non-combustible materials having a fire-resistance rating of not less than half an hour.

(6) All floors constructed directly over basements shall have a fire-resistance rating of not less than one hour.

(7) All floors, other than those referred to in subsections (5) and (6), shall have a fire-resistance rating of not less than half an hour:

Provided that no fire-resistance rating shall be required for such floors in the ground storey, if the space beneath such floors is not used for storage purposes.

(8) Roof assemblies. – The roof of every building having external walls of combustible construction shall be covered with non-combustible materials.

(9) Every building having a roof covered with thatch or wooden shingles shall be not less than 10 metres from any boundary whatsoever of the stand upon which such building is to be erected.

(10) All metal used in the attachment of thatch to the roof-members shall be bonded to earth.

(11) All telephone and electricity supply-lines shall be brought by means of underground conduits or cables into every building which has a thatched roof.

(12) Partition-walls. –Every partition-wall in a basement shall be of non-combustible materials. Every doorway in such partition-wall shall be fitted with a fire-door having a fire-resistance rating of not less than half an hour.

(13) Garages. –Every floor separating the remainder of the building from a garage shall be regarded as forming part of an occupancy-separation structure, which shall comply with the requirements of section 43 and shall have no openings whatever therein.

(14) Every wall separating the remainder of the building from garage shall comply with the requirements for an occupancy-separation structure set out in setion43, except that any doorway in such wall shall be fitted with a self-closing door constructed to have a fire-resistance rating of not less than half an hour, and every such doorway shall have a solid stone or concrete threshold raised at least 100 millimetres above the floor of the garage.

11.FIRE_RESISTANCE RATING OF SUPPORTING STRUCTURAL MEMBER.

All supporting structural members in buildings shall have a fire-resistance rating of not less than the required rating of the construction supported by such members.

12. DIVISION WALLS AND DIVISION FLOORS.

(1) Where a building is divided into divisions, as required by section 6, all division-walls and division-floors shall comply with the requirements of this section.

(2) Fire-resistance rating. – Every division-wall and every suspended floor which is a division-floor shall be of non-combustible material, and shall have a fire-resistance rating of not less than four hours.

(3) Every division-wall shall be constructed as a continuous wall, or as a number of storey-to-storey walls, not necessarily in one vertical plane:

Provided that, where such walls are not in one vertical plane, the floor construction connecting such walls shall have a fire-resistance rating of not less than four hours.

(4) Every division-wall, whether continuous or not, shall –

a) Rest on a construction having a fire-resistance rating of not less than four hours; and

b) Extend to not less than 300 millimetres above the roof-covering:

Provided that, in the following cases, such wall need only be carried up against the underside of the roof-covering, for the full thickness of the wall –

a) Where the roof construction is non-combustible, and collapse thereof on one side of the wall would not endanger the stability of such wall;

b) Where the difference in the height of the roofs of divisions of a building exceeds 1 metre at division-wall, and the roof construction is non-combustible.

(5) Division-floors shall be continuous over the area of the division, except for openings enclosed, as set out in subsection (9).

(6) Openings in division-walls. – Openings in any division-wall shall not exceed 12 square metres in area, and shall have no dimension greater than 3,6 metres.

(7) The aggregate width of all such openings at any storey-level shall not exceed 25 per centum of the length of the wall in which such openings are formed.

(8) Every opening in a division-wall shall be protected by an approved automatic or self-closing fire-door or fire-shutter, and the aggregate fire-resistance rating of the door or shutter shall be not less than four hours:

Provided that, where such opening occurs in the walls between two buildings, a door or fire-shutter shall be required on each side of the walls.

(9) Openings in division-floors. – Every opening in a division-floor shall be protected by an enclosed shaft, and any opening in such shaft shall be fitted with an approved automatic or self-closing fire-door or fire-shutter, and the enclosing-walls and such door or shutter shall have a fire-resistance rating of not less than one and a half hours

(10) Protection of openings in eternal walls at division-floors. – Where a division-floor abuts external walls, the risk of the passage of fire past such floor shall be reduced by protecting the openings here-in after referred to in such walls by non-opening or self-closing fire-windows or shutters, or self-closing fire-doors, having a fire-resistance rating of not less than half an hour, so disposed that every opening within a horizontal band of the external walls of not less than 7,5 metres in height is so protected, and such brand shall overlap the division-floor and be situated above, below or partly above and partly below the division-floor:

Provided that the openings in such external walls need not be protected, as prescribed above, if a canopy or hood of non-combustible material having a fire-resistance rating of not less than one hour is constructed as an extension of the division-floor to project not less than 1,5 metres beyond the exterior face of the external wall abutting the division-floor.

(11) If a canopy or hood is constructed, as in the provision to subsection (10), such canopy or hood shall be provided under every opening in such wall, within a height of 7,5 metres above the division-floor, and shall extend not less than 1,5 metres beyond the vertical lines drawn through the sides of every such opening.

13.OCCUPANCY-SEPARATION STRUCTURES AND TENANCY-SEPARATION STRUCTURES.

(1) Occupancy-separation structures and tenancy-separation structures shall comply with the requirements of this section.

(2) Fire-resistance ratings. – All occupancy-separation structures shall be constructed of non-combustible material, and such occupancy-separation structures and all tenancy-separation structures shall have fire-resistance ratings of not less than the ratings specified in Table XI.

TABLE XI

FIRE_RESISTANCE RATINGS OF OCCUPANCY-SEPARATION STRUCTURES AND TENANCY-SEPARATION STRUCTURES.

| 1 | 2 |

| Description of structure | Fire resistance rating in hours |

| Occupancy-separation structure separating an occupancy unit high of high fire load from one of high and moderate or low fire load | |

| Occupancy-separation structure separating an occupancy unit high of moderatefire load from one of high and moderate or low fire load | |

(3) Construction of occupancy-separation structures. – Every wall of an occupancy-separation structure shall extend from a foundation or floor of non-combustible construction to a ceiling or floor of non-combustible construction:

Provided that, where a ceiling is of combustible material, such wall shall extend through such ceiling to a non-combustible floor or roof construction and, where the roof is of combustible construction, such wall shall be carried through such roof to not less than 300 millimetres above the covering of such roof.

(4) Suspended floors in an occupancy-separation structure shall be continuous over the area of the occupancy-unit concerned, except for openings protected, as set out in subsection (6).

(5) Openings in occupancy-separation structure. – Every wall of an occupancy-separation structure shall have no openings other than doorways, and every such doorway shall be fitted with an approved self-closing fire-door having the appropriate fire-resistance rating set forth in Table XI

(6) Every opening in the floor of an occupancy-separation structure shall be protected by an enclosed shaft, and any opening in such shaft shall be fitted with an approved self-closing fire-door or shutter, and such shaft shall have a fire-resistance rating of on and a half hour, and such door or shutter shall have a fire-resistance rating of one hour.

(7) Penetration of occupancy-separation structure walls by combustible materials. – No combustible material shall pass through an occupancy-separation structure wall:

Provided that –

i) Rafters, joists, bearers and beams of combustible materials may be built into such wall, if the remaining thickness of the wall has the appropriate fire-rating set out in Table XI; and

ii) Light, combustible roof-members, such as battens and purlins, may be built into such wall, is such members are separated from one another by non-combustible material of not less than 75 millimetres in width and of depth of not less than the depth of such members.

14. OPENINGS IN EXTERNAL WALLS.

(1) Places of worship not exceeding three storeys in height, dwelling-houses and open-air parking-garages shall be excluded from the provisions of this section.

(2) In this section, “opening” shall mean any portion of an external wall which has a lower fire-resistance rating than that prescribed in this Chapter for such wall, but shall not include any window, less than 0,5 square metre in an area which serves a water-closet, bath-room or cloak-room:

Provided that, if any two or more windows are not separated from one another by a horizontal distance of at least 215 millimetres or a vertical distance of at least 1,2 metre, they shall be regarded as one opening.

(3) The fire protection of openings in external wall of a building shall be as set forth in Table XII, when the distance from such an opening to the nearest lateral boundary of the stand on which such building is erected, or to another building on the same stand is the relevant distance set out in that Table:

Provided that such protection need not be provided to openings facing a lateral boundary, if there is erected on such boundary a baffle-wall having a fire-resistance rating of not less than one and a half hours, and of such a height and length as will, in the opinion of the local authority, render the protection of such openings unnecessary.

(4) Where an external wall of one building is built against an external wall of another building, and an opening is formed in both such walls so as to provide means of access between such buildings, the opening so formed shall be deemed to be an opening in a division-wall, and such opening shall be protected on each side of such composite wall by approved fire-doors or fire-shutters having an aggregate fir-resistance rating for both doors or both shutters of not less than four hours.

(5) Any opening formed in an external wall of a building, which opening is within the range of distances from the nearest lateral boundary of the stand on which such building is erected or from another building on the same stand set out in column 2 of Table XII, shall be fitted with an approved automatic or self-closing fire-door or fire-shutter having a fire-resistance rating of not less than one and a half hours.

(6) Any opening formed in an external wall of a building, which opening is within the range of distances from the nearest lateral boundary of the stand on which such building is erected or from another building on the same stand set out in columns 3 and 4 of Table XII, shall be fitted with an automatic or a self-closing fire-door or fire-shutter having a fire-resistance rating of not less than one hour.

(7) Any opening formed in an external wall of a building, which opening is within the range of distances from the nearest lateral boundary of the stand on which such building is erected or from another building on the same stand set out in columns 5 and 6 of Table XII, shall be fitted with an approved non-openable or self-closing fire-window or with an approved automatic or self-closing fire-door or fire-shutter, and every such window, door or shutter shall have a fire-resistance rating of not less than half an hour.

(8) Any external wall of building, in which the total area of openings or the total use of combustible exterior wall-lining exceeds 55 per centum of the area of such wall, shall be not less than 9 metres from any lateral boundary of the stand on which such building is erected or from another building on the same stand and facing such wall, and not less than 6 metres from the centre-line of any street exceeding 4,5 metres in width.

(9) The distances referred to in the foregoing subsections shall be taken as the least distance between the opening or the wall, as the case may be, and the nearest lateral boundary or building concerned.

TABLE XII

FIRE PROTECTION OF OPENINGS IN EXTERNAL WALLS REQUIRED IN RELATION TO DISTANCE

(10) Subject to the provisions of subsection (10) of section 12, any opening which is located vertically above or below another opening on an external wall and which is not protected by a fire-shutter or fire-door or a fire-wind shall be –

a) Separated by a vertical distance of not less than 1,2 metres from such other opening; or

b) Protected by a hood or canopy under the opening, projecting not less than 1 metre from the wall-face, and projecting not less than 1 metre beyond the vertical lines drawn through the sides of every such opening.

(11) If a hood or canopy is constructed in accordance with the provisions of paragraph (b) of subsection (10), such hood or canopy shall be of non-combustible material and shall have a fire-resistance rating of not less than one hour.

15. SERVICE-SHAFTS.

(1) The provisions of this section shall not apply to shafts in dwelling-houses or to shafts enclosing stairways, air-ducts, incinerator-chutes, flues and ramps connecting storeys in buildings.

(2) All lift-shafts and hoist-shafts in a building shall be enclosed by walls having a fire-resistance rating of not less than on and a half hours. In such shafts, there shall be at least one opening in every 9 metres of the height of the shaft, fitted with an approved self-closing fire-door having a fire-resistance-rating of not less than one hour.

(3) Any enclosed shaft extending through the roof, and which is enclosed at the top, shall be provided with a lantern-light having unglazed or glaze openings equivalent in are to not less than 20 per centum of the cross-sectional area of such shaft, and, where such openings bare glazed, they shall be glazed

TABLE XII FIRE PROTECTION OF OPENINGS IN EXTERNAL WALLS REQUIRED IN RELATION TO DISTANCE

| 1 | 2 | 3 | 4 | 5 | 6 | |

| Class or grade of construction of building | Where the distance to lateral boundary or another building on the same stand is as shown, requirements for openings in walls shall be as shown in the headings to columns 2-7 set out below | |||||

| Only doorway openings: all such openings to be fitted with fire-doors or fire-shutters complying with subsection (5) | Area of each opening not to exceed 5 square meters All openings to be fitted with fire-doors or fire-shutters complying with subsection (6) | All openings to be fitted with fire-windows, fire-doors or fire-shutters complying with subsection 7) | No requirement | No requirement | ||

| Least distance, in meters | ||||||

| less than | not less than, | but less than | not less than, | not less than | ||

| Class 1, and the storage contemplated by section 44 | 4.5 | 4.5 | 6.0 | 6.0 | 7.5 | 7.5 |

| Other buildings (all grades of construction of high fire loads | 3.0 | 3.0 | 3.75 | 3.75 | 4.5 | 4.5 |

| Other buildings (all grades of construction of low fire loads | 1.5 | 1.5 | 2.25 | 2.25 | 3.0 | 3.0 |

with plain glass of not more than 3 millimeters in thickness:

Provided that instead of such lantern-light, a window glazed with similar glass and of equal area placed in the side of such shaft may be provided if—

a) The sill of such window is not less than 600 millimetres above the roof-covering at any point of the sill; and

b) Such window is not within 3 metres of a lateral boundary.

(4) Any shaft enclosure which does not extend through the roof shall have the top of such enclosure enclosed by a construction having a fire-resistance rating of not less than that of the walls of the shaft, and shall be provided with a ventilating-duct leading to the outside air.

(5) The ventilating-duct referred to in subsection (4) shall have a cross-sectional area equal to not less than 10 per centum of the cross-sectional area of the shaft, and the discharge-end of such duct may be glazed with plain glass not exceeding 3 millimetres in thickness.

(6) Any shaft which does not extend to the bottom of a building shall be enclosed at its lowest point by a floor construction having a fire-resistance rating of not less than that of the walls of the shaft

(7) Any room containing machinery for operating lifts shall be separated from the lift-shaft concerned by construction having a fire-resistance rating of not less than two hours.

(8) Every doorway in a room containing machinery for operating lifts shall be fitted with an approved self-closing fire-door having a fire-resistance rating of not less than one hour.

16. ROOF-LIGHTS AND FLOORS-LIGHTS.

(1) All frames and sashes of skylights, lantern and other similar lights shall be of metal:

Provide that, where such roof-lights are constructed –

a) In dwelling-houses; or

b) In localities where the roof-lights would be exposed to agencies deleterious to metal;

The local authority may permit the frames and sashes to be made of some other suitable material.

(2) All lights referred to in subsection (1) which are –

a) Less than 3 metres from a lateral boundary or an exit-way, and such lights which are inclined at an angle of less than 60 degrees to the horizontal shall be glazed with wired glass of not less than 6 millimetres in thickness; and

b) In positions other than those described in paragraph (a), may be glazed with plain glass.

(3) Every skylight which is glazed with plain glass shall be protected by a substantial wire screen, with wire not lighter than 2,5 millimetres and having a mesh not greater than 15 millimetres, placed not less than 100 millimetres or more than 250 millimetres above the glazed portion of the skylight at all points.

(4) Such screen shall extend beyond the glazing on all sides for a distance of not less than the height of the screen above the glazing.

(5) Where a skylight or lantern-light is located over a stairway, exit-way or an indoor public and assembly occupancy, a similar screen shall also be placed below such skylight or lantern-light.

(6) Notwithstanding any other provision of this section, but subject to the approval of the local authority, roofs may be covered with materials made of incombustible or self-extinguishing plastics or other similar materials up to 10 per centum of the total roof area

(7) Floor-lights of glass or other translucent and brittle material shall not be allowed in floors between the storeys of a building, unless they have a fire-resistance rating equal to that of the floor in which they are contained and comply with any other requirements of these by-laws relating, amongst others, to artificial lighting.

17. ACCESS TO ROOF-SPACES.

(1) Any opening which gives access to a roof-space in a sloping-roof assembly through a ceiling, or through a subdividing-wall in such roof-space, shall be fitted with a non-secured cover or door having a fire-resistance rating of not less than that of the ceiling in the roof assembly concerned.

(2) Such cover or door shall be so constructed that it will remain closed when not in use.

(3) The size of such opening shall be not greater than 1 × 1 metre and not less than 600× 750 millimetres.

18. SERVICE-PIPES AND EQUIPMENT SET IN STRUCTURAL MEMBERS.

(1) Fixing. – Service-pipes, cables and other service equipment may be embedded in the fire-resistant protection to, and construction of, columns and other structural members if –

a) After such equipment is fixed, such members still maintain the required fire-resistance rating and the thickness of fire-resistant protective covering, as laid down in Tables IV and V of the Second Schedule; and

b) The service equipment is so fixed that the required fire-resistance rating of the member concerned is not impaired by any subsequent maintenance or replacement of such equipment.

(2) Protection of fire-resistant protective covering. – Where the fire-resistant protective covering to columns and other structural members is exspoed to the risk of damage, as, for example, from vehicular traffic, or the handling of merchandise, such covering shall be protected by vertical guards or by wheel-guards or other approved means of protection

19.FIRE-STOPPING.

(1) Fire-stopping to the extent specified in this section shall be carried out with non-combustible material:

Provided that, in the case of walls and partitions of timber-frame construction, timber of not less than 38 millimetres in thickness may be used in fire-stops.

(2) Spaces in fire-resistant protective coverings. –

Any spaces between the fire-resistant protective covering and columns or other structural members shall be fire-stopped at each storey level, and the fire-stops shall extend for the thickness of the floor of such storey.

(3) Spaces in wood-floor construction. – Where joists or bearers are parallel to, and are 75 millimetres or less from a wall or chimney, the space between the joists or bearer and the wall or chimney shall be fire-stopped to the depth of the joists or bearer.

(4) Spaces between walls and wall-linings. – In buildings of grade A construction, spaces between walls and wall-linings or panelling shall be completely fire-stopped.

(5) In buildings, other than buildings of grade A construction, such spaces shall be fire-stopped at each floor and ceiling-level.

(6) Spaces in chases and recesses. – Where chases or recesses pass from one storey to another, such chases or recesses shall be fire-stopped at each storey-level, and the fire-stops shall extend for the thickness of the floor of such storey.

(7) Spaces around pipes and ducts. – All spaces around pipes or ducts in every storey shall be fire-stopped at each floor, ceiling or wall of such storey.

(8) Walls and partitions of stud-framing. – All walls and partitions of stud-framing shall be fire -stopped at the floors and ceilings of every storey.

20. ACCESS FOR RESCURE AND FIRE_FIGHTING PURPOSE.

(1) Every building, other than a single-storey building not exceeding 55 square metres in floor area, which does not have a frontage on to a street r public place, shall have access from such street or public place by means of an unobstructed passage way of not less than 3 metres in width, having a clearance of not less than 4,2 metres in height.

(2) Similar access shall be provided from a street or public place to buildings exceeding three storeys in height which have no frontage on a street or public place, and such access shall lead to an open space adjoining the building of at least 4,5 metres in width and 12 metres in length.

(3) In any storey of any building above the ground in which all openings in any length exceeding 45 metres of a wall facing a street or public place or passageway referred to in subsection (1) are fitted with automatic fire-shutters or any other shutters which may bar entry from the outside, at least one shutter in every 45-metre length of such wall shall be readily openable from the outside, and shall bear an approved notice or mark clearly legible from such street, place or passageway.

(4) Where there is erected in front of any building facing a street or public place or passageway referred to in subsection (1) a screen or screen-wall which would otherwise bar entry to windows from the outside, there shall be provided, in such screen or screen-wall, openings of not less than 750 millimetres in width and of not less than 1,2 metres in height.

(5) At least one such opening shall be provided in every 45-metre length of such screen or screen-wall in every storey above finished ground-level, including the ground storey, up to and including the sixth storey.

(6) In any building or portion thereof in which there are no windows in the external walls, access openings shall be provided in such walls for fire-fighting purposes in each storey above finished ground-level, including the ground storey, up to and including the sixth storey.

(7) Such openings shall be not less than 750 millimetres in width and not less than 1,5 metres in height and have a sill not more than 1 metre above the inner floor-level of each storey, and shall be not more than 45 metres apart horizontally.

(8) Every such opening shall be fitted with a shutter readily openable from the outside, and shall bear an approved notice or mark clearly legible from the ground below.