| Section | Section | ||

| Aggregate Coarse …………….. | 5(8) | Empirically constructed Brick | 52(1) |

| Fine …………….. | 5(5) & 6 | Masonry | 30 |

| Anchorage to joisted timber and precast concrete floors | . . 25 | Design Constructed of masonry construction | 63 &82 |

| Arches over openings | 17 | Design general requirements for | 64 |

| Balustrade -walls empirically constructed Brick | 53(3) | Dimensions subject to tolerances | 3 |

| general | 27(7) | Dispersion forces | 65 |

| Basement -walls, empirically constructed brick | 46 | eccentric or lateral forces stresses due to | 72 |

| Beams & rafters ends of | 24 | empirical construction bearings for beams other than timber in | 41 |

| Beams, other than timber in empirical construction bearings for | 41 | minimum requirements for materials for | 42 |

| Block masonry axial stresses in | 69 | Existing masonry, use of | 16 |

| Blocks cay, concrete, glass and sand -cement. | 5(9) & (10) | External walls to be weatherproof, | 6 |

| gypsum general requirements for | 36 | Faced walls | 29 |

| hollow glass, general requirements for | 37 | Facings, veneer (see under Veneered Walls) | |

| soil cement | 5(12) | Floors joisted timber and precast concrete, anchorage to. | 25 |

| Bond | 11 | loadings and spans in empirical construction | 39 |

| breast -Walls | 27 (8) | Foundation-walls, empirically constructed brick | 46 |

| Brick mansonry basic stresses | 67 | Free-standing walls, empirically constructed brick | 55 |

| Bricks cement clay and sand lime | 5(9) | Glass blocks, hollow, general requirements for | 37 |

| Soil cement | 5(12) | Grout for reinforced brickwork | 77 |

| Brick walls (see under walls) | Gypsum blocks, general requirements for | 36 | |

| Building units ,masonry , general for soil cement | 34 | blocks, requirements for empirical construction | 60 |

| empirically constructed | 59 | mortar | 13(14) to (16) |

| general requirements for | 35 | Height, total permissible for empirically constructed brick bearing walls. | 45 |

| standard | 5(9) | Impact tests for walls, including panel- walls. | First schedule |

| Calculated design of masonry and walling | 63-82 | Interpretation of certain terms | 2 |

| Cavity –walls empirically constructed brick | 49 | Interpretation of terms | 1 |

| general | 33 | Joints in masonry bond | 11 |

| cement used in mansory | 5(3) | workmanship | 12 |

| Chases and recesses | 17(2)to(6) and 39 | Lateral or eccentric forces, stresses due to | 72 |

| Cold weather construction in | 15 | Lime used in masonry | 5(4) |

| Columns empirically constructed brick | 50 | Lintels general | 18 |

| empirically constructed plain normal concrete | 61 | over openings | 17(1) |

| reinforced -brick detailed requirements for | 79 | Load-bearing surfaces | 10 |

| reinforced -concrete | 74(4) | Loading of masonry members | 9 |

| concrete cast in situ, axil stresses in | 70 | Loadings and spans of floors and roofs in empirical construction | 39 |

| Columns reinforced | 74(4) | Loads, concentrated, stresses under | 73 |

| in walling | 14 | Retaining walls empirically constructed brick | 56 |

| Lintels reinforced | forth scedule | general | 26 |

| no fines empirical construction in | 62 | of natural stone | 58(3) |

| no fines empirical construction for | 38 | Roof, thrust from | 20 |

| Plain normal empirically constructed walls of | 61 | Roofs, loadings and spans in empirical construction | 39 |

| walls reinforced | 74(1)to(3) | Rubble stone for masonry | 5(11) |

| corbelling | 21 | Sand used in mortar and concrete | 5(5)and (6) |

| cornices | 23 | Slenderness ratio effective height of columns and walls. | Table XVI |

| Cross walls | 19 | effective thickness of stiffened walls | Table XVII |

| Mansonry (empirically constructed ) blocks | 57 | general | 66 |

| gypsum blocks | 60 | permissible limits of | Table XIX |

| natural stone | 58 | Soil-cement building units general requirements for | 35 |

| soil-cement building units | 59 | requirements for empirical construction of | 59 |

| Mansonry (general) block axial stresses in | 69 | standard building units | 5(9) |

| brick basic stresses for | 67 | Stiffened walls, factors for | FIFTH SCHEDULE |

| Buidling -units general requirements for | 34 | Stiffeners for hollow glass blocks in masonry walls | 37(11) and (13) |

| existing use of | 16 | Stone for masonry | 5(11) |

| natural stone axial stresses in | 71 | Stone masonry, natural axial stresses in | 71 |

| Materials for empirical construction , minimum requirements for. | 42 | ||

| for reinforced brickwork | 76 | empirically constructed. | 58 |

| not provide for in the bylaws | 5(1) | “Storey” dimensions permissible for empirically constructed brick bearing- walls | 44 |

| second hand | Strength, compressive and mixing proportions of mortar | 13(7) | |

| unspecified walling of | of building units for empirical construction | 42 | |

| Mortar general | 13 | of concrete in walling | 14(4) |

| cubes testing of , for compressive strength | third schedule | testing mortar cubes for | third schedule |

| for glass blocks in masonry walls | 37(13) | Stresses axial, in block masonry | 69 |

| for reinforced brickwork | 77 | axial, in cast-in-situ concrete | 70 |

| Joints in masonry (workmanship) | 12(3) | axial, in natural stone masonry | 71 |

| basic, for brick masonry | 67 | ||

| Natural stone masonry axial stresses in | 71 | due to eccentric or lateral forces | 72 |

| empirically constructed | 58 | for large slenderness ratios | 68 |

| No-fines concrete empirical construction in | 62 | permissible in reinforced brickwork | 78 |

| general requirements for | 38 | under concentrated loads | 73 |

| openings chases and recesses | 17 | Support of walls | 8 |

| overhanging walls | 22 | Surfaces, load-bearing | 10 |

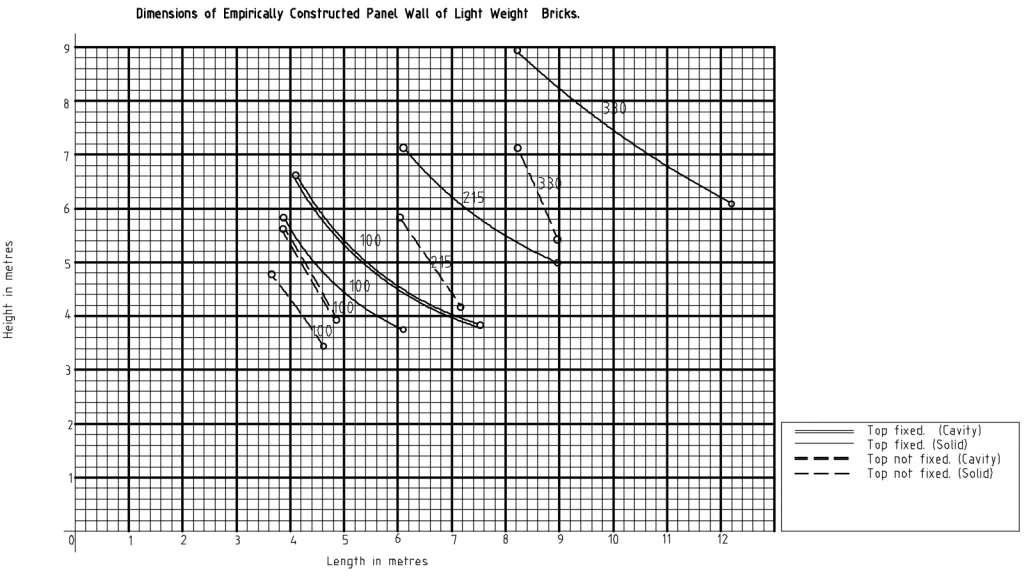

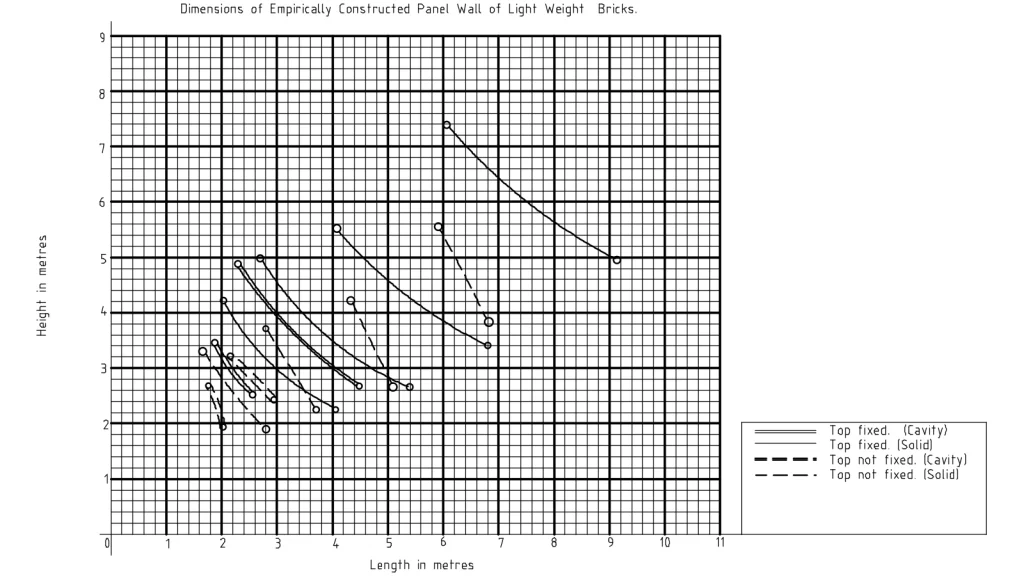

| Panel -walls empirically constructed brick | 52(2) to (6) | Tests impact, for walls, including panel-walls | First schedule |

| general | 31 | moisture penetration, for walls, artificial rain test. | Second schedule |

| impact test for | first schedule | of mortar cubes for compressive strength | Third schedule |

| Parapet-walls empirically constructed brick | 53(1) and (2) | Thrust from roof | 20 |

| general | 27(1)to (6) | Tolerances, dimensions subject to | 3 |

| Partition walls empirically constructed brick | 54 | Unspecified materials, walling of | 7 |

| general | 32 | Veneer, dimensions of empirically con- structed walls carrying heavy | 43 |

| Rafters and beams ends of | 24 | Veneered walls | 28 |

| recesses and chases | 17( 2) TO (6) | Walls (general) balustrade- | 27(7) |

| Reinforced brick columns detailed requirements for | 79 | breast- | 27(8) |

| Reinforced brick walls detailed requirements for | 80 | cavity- | 33 |

| Reinforced brick work cover over reinforcement in | 81 | Cross- | 19 |

| general requirements for | 75 | curtain-, masonry | 30 |

| materials for | 76 | faced | 29 |

| miscellaneous requirements for | 82 | overhanging | 22 |

| mortar and grout for | 77 | panel. | 31 |

| permissible stresses in | 78 | parapet- | 27(1) to (6) |

| Reinforced concrete columns and walls | 74 | partition.. | 32 |

| lintels | fourth schedule | reinforced-brick | 80 |

| wall-sections between openings in empirically constructed walls | 40 | reinforced-concrete | 74(1) to (3) |

| walls (empirically constructed ) brick | retaining. | 26 | |

| above the roof | 48 | veneered | 28 |

| balustrade | 53(3) | Water used in masonry or concrete walling | 5(7) |

| basement | 46 | Weather, cold, construction in | 15 |

| bearing 100 mm thick | 47 | Weatherproof, external walls to be | 6 |

| cavity | 49 | Wing-walls, empirically constructed brick | 51 |

| curtain | 51(1) | Workmanship | 12 |

| foundation | 46 | ||

| free standing | 55 | ||

| panel | 52(2)to(6) | ||

| parapet | 53(1) and (2) | ||

| partition | 54 | ||

| retaining | 56 | ||

| wing | 51 | ||

| brick bearing | |||

| permissible “storey” dimensions | 44 | ||

| permissible total height | 45 | ||

| concrete no fines | 62 | ||

| plain normal | 61 |

ARRANGEMENT OF SECTIONS

PRELIMINERY

SECTION

1.Interpretation of terms.

2. Interpretation of certain terms.

3.Dimensions subject to tolerances.

PART I

ERECTION OF MASONRY IN BUILDINGS

4. Application of regulations to masonry and concrete walling.

5. Requirements for materials and building-units.

6. External walls to be weatherproof.

7. Walling of unspecified materials.

8. Support of walls.

9. Loading of masonry members.

10. Load-bearing surfaces.

11. Bond.

12. Workmanship.

13. Mortars.

14. Concrete in walling.

15. Construction in cold weather.

16. Use of existing masonry.

17. Openings, chases and recesses.

18. Lintels.

19. Cross-walls.

20. Thrust from roof.

21. Corbelling.

22. Overhanging walls.

23. Cornices.

24. Ends of beams and rafters.

25. Anchorage to joisted timber and precast concrete floors.

26. Retaining-walls: general.

27. Parapet-walls, balustrade-walls and breast- walls.

28.Vennerd wall

29. Faced wall

30. Masonry curtain walls

31. Panel walls

32. Partition walls

34. Cavity walls: general

35.General requirements for hollow masonry walls

36. Genral requirements for soli cement walls.

37. General requirements for hollow glass blocks.

38. General requirements for no-fines concrete.

PART II

GENERAL REQUIREMENTS FOR EMPIRICAL MASONRY CONSTRUCTION

39. Floors, roofs, chases, recesses and panel-walls in empirical construction.

40.Wall-sections between openings in empirically constructed walls.

41.Bearings for beams other than timber in empirical construction.

42. Minimum requirements for materials for empirical construction.

43. Dimensions of empirically constructed walls carrying heavy veneer.

PART III

REQUIREMENTS FOR EMPIRICALLY CONSTRUCTED MASONRY AND CONCRETE A. BRICK BEARING-WALLS

44. Permissible “storey” dimensions for empirically constructed brick bearing-walls.

45.Permissible total height for empirically con- structed solid-brick bearing-walls.

46.Empirically constructed brick foundation- walls and basement-walls.

47.Empirically constructed brick bearing walls 100 millimeters in thickness.

48.Empirically constructed brick walls above the roof.

49. Empirically constructed brick cavity-walls.

50. Empirically constructed brick columns.

51. Empirically constructed brick wing-walls.

B. BRICK NON-BEARING WALLS

52.Empirically constructed brick curtain-walls and panel-walls.

53.Empirically constructed brick parapet-walls and balustrade-walls.

54. Dimensions of empirically constructed brick partition-walls.

55. Dimensions of empirically constructed brick free-standing walls.

56. Dimensions of empirically constructed brick retaining-walls.

C. MASONRY OTHER THAN BRICK

57.Dimensional requirements for empirically constructed masonry of blocks.

58. Requirements for empirically constructed masonry of natural stone.

59.Requirements for empirically constructed masonry of soil-cement building-units.

60.Requirements for empirically constructed masonry of gypsum blocks.

D. CONCRETE

61.Empirically constructed plain normal con- crete walls and columns.

62.Empirical construction in no-fines concrete.

PART IV

CALCULATED DESIGN OF MASONRY AND WALLING

A. GENERAL

63. Application of certain sections.

64.General requirements for design.

65. Dispersion and application of forces.

66. Slenderness ratio.

67. Basic stresses for brick masonry.

68. Stresses for large slenderness ratios.

69. Axial stresses in block masonry.

70.Axial stresses in cast-in-situ concrete.

71.Axial stresses in natural stone masonry.

72. Stresses due to eccentric or lateral forces.

73. Stresses under concentrated loads.

74.Reinforced-concrete walls and columns.

B. SPECIAL REQUIREMENTS FOR REINFORCED BRICKWORK

75.General requirements for reinforced brick- work.

76.Materials for reinforced brickwork.

77.Mortar and grout for reinforced brickwork.

78.Permissible stresses in reinforced brickwork.

79.Detailed requirements for reinforced-brick columns.

80.Detailed requirements for reinforced-brick walls.

81. Cover over reinforcement in reinforced brick- work.

82. Miscellaneous requirements for reinforced brickwork.

FIRST SCHEDULE: Impact tests for walls, including panel-walls.

SECOND SCHEDULE: Moisture penetration test for walls: artificial rain test.

THIRD SCHEDULE: Testing mortar cubes for compressive strength.

FOURTH SCHEDULE: Reinforced-concrete lintels.

FIFTH SCHEDULE: Factors for stiffened walls.

PRELIMINERY

1. INTERPRETATION OF TERMS.

In this Chapter –

“adequate lateral support”, in relation to a wall, means a cross-wall complying with the requirements of section 19, or a structural member which is designed to resist the overturning moments and lateral forces on the wall supported, or a column, buttress, frame or other construction which is, in the opinion of the local authority, adequately to do so;

“admixture” means a material other aggregate, cement or water, added in small quantities during the mixing of concrete to produce some desired modification in one or more of the properties of the concrete;

“aggregate” means a material which is mixed with cement and water to provide bulk in concrete or mortar;

“coarse aggregate” means aggregate complying with the provisions of subsection(8) of section 5;

“fine aggregate” means aggregate having with the provisions of subsections(5) and (6) of section 5;

“light-mass aggregate” means aggregate having a density of not more than 1000 kilograms per cubic meter, measures loose and dry;

“ordinary aggregate” means aggregate other than light-mass aggregate;

“ashlar masonry” means masonry composed of rectangular units of natural or cast stone which have larger exposed face-areas than those of blocks, and have accurately sawn, dressed, cast or squared beds, and are co laid in mortar that the joints not less than 3 millimeters and not more than 8 millimeters in thickness;

“balustrade” means a row of columns crowned by a railing erected along the edge of a balcony or gallery to prevent persons from falling;

“bearing-plate or padstone” means a block of material, placed under the end of a roof-truss, girder or beam, to distribute the load;

“block” means a masonry-unit used in building, and possessing dimensions such that it can be laid only in a non-bonded or stretcher bond pattern;

“cellular blocks” means blocks which are similar to hollow blocks but which have the cavities closed at one end. The solid cross-sectional area of a cellular block shall comprise at least 45 per centum of the total cross-sectional area of that block;

“hollow blocks” means blocks which-

a) contain at least one large hole or cavity of a size such that the solid material in the block constitutes between 48 per centum and 75 per centum of the total volume of the block calculated from its over-all dimensions; or

b) when used in a wall, or in a leaf of a cavity wall, forms internal cavities which have a total area, in the horizontal plane, or more than 25 per centum of the horizontal cross-sectional area of the wall or leaf of the cavity wall;

“solid blocks” means blocks in which the solid material is not less that 75 per centum of the total volume of the block calculated from over all dimensions;

“bond”, as applied to-

a) masonry, means a systematic arrangement of bricks or other building-units in courses, which will enable them to act together as a whole in sustaining loads, and “to bond” has a corresponding meaning;

b) reinforcement, means the shear stress developed at the interface between a reinforcing-bar embedded in concrete or mortar and the surrounding concrete or mortar when an axial force is applied to the bar, the bond stress tending to restrain relative displacement of the bar;

“brick “ means a masonry-unit used in building and possessing dimensions such that it can be laid with the use of any acceptable masonry bonding pattern;

“building-unit” means a brick or block of clay, concrete, calcium silicate, soil-cement or other material, of regular shape or a natural stone or rectangular or irregular shape and size, used in construction of masonry or walling;

“buttress” means a vertical member bonded into a wall for the purpose of giving it lateral support. It resembles a pier but does not extend to the full height of the wall;

“cast stone” means a reconstructed or artificial stone consisting of a mixture of cement and aggregate;

“column” means a vertical load-bearing member measured at right angles to its thickness, does not exceed four times the thickness, and which is not bonded into a wall;

“concrete” means a mixture of cement, aggregate and water, with or without admixtures, which has, or will set to form a hard, cohesive agglomeration;

“light-mass concrete” means concrete having a density less than 1600 kilograms per cubic metre after it has been cured and become air-dry

“no-fines concrete” means concrete containing not more than 10 per centum fines of the total mass of aggregate;

“normal concrete” means concrete containing both fine and coarse aggregate;

“corbel” means a projection built out from the face of a wall to form a load-bearing surface;

“cornice” means a horizontal projection which crowns or finished a wall or any portion of a wall or any other architectural feature;

“empirically constructed” means constructed or intended to be constructed otherwise than in accordance with a design based on calculation of the dimensions required to limit, to the values set out in sections 67 to 74 or in section 78, the stresses which could occur in the masonry or walling, and “empirically construction” shall have a corresponding meaning;

“foundation-footing” means a foundation, not being a pile, supporting a structural member, and usually wider than the structural member;

“height of the wall or column”-

a) “effective height” of a wall or column, means the height of a wall or column assumed for calculating its slenderness ration;

b) “storey-height” of a wall or column, in any storey, means the height of a wall or column measured from the underside of the floor construction of such storey to the under-side of the floor construction immediately above, or when there is no floor above, to the mean height is no floor above, to the mean height of the gable, where the wall is a gable-wall, or to the underside of the roof construction above, whether this be a wall-plate, girder or other framework:

Provided that-

i) where such wall or column is not laterally restrained by the floor, its storey-height shall be measured from the top of the foundation; and

ii) where a column rests centrally on a foundation-wall which is at least 100 millimetres thicker than the column, the storey-height of such column may be measured from the top of such foundation wall;

c) “total height” of a wall or column means heights measured from the top of the foundation -footing girder or slab on which the wall or column rests to the top of the wall or column, whether or not this is above the roof:

Provided that the total height of a gable-wall shall be taken as its mean height:

“length of wall”-

a) “effective length of a wall” means the length of wall assumed for calculating its slenderness ratio;

b) “unbroken length wall” means a length of wall which is not broken into by opening or by chases or recesses which are regarded as openings in terms of section 17;

c) “unsupported length of wall” means the length of the wall measured between the inner faces of adequate lateral support to a free end;

“light-mass construction” means construction in which the walls in any storey and in all storeys above are built entirely of bricks or blocks having density less than 1 600 kilograms per cubic metre of gross volume, or light-mass concrete;

“masonry” means an assembly of non-combustible building-units bonded together;

a) “masonry construction” means construction of masonry or of masonry in combination with other materials;

b) “solid masonry” means masonry in which the building-units are laid with the joints between such units filled with mortar, and without forming cavities between unit;

“masonry-unit”: see “building unit”;

“mortar” means a mixture of cement or lime, or both, with fine aggregate and water;

“pier” means a vertical masonry member bonded into a wall and of the same height as the wall;

“sleep-pier” see “sleeper-wall” or “sleeper-pier”

“restrained”-

a) “a column fully restrained at the top” means a column adequately restrained at the top from movement in position or direction in the plane being considered;

b) “a wall fully restrained at the top” means a wall supporting a solid concrete beams bonded to the wall, or a wall anchored to a precast concrete floor as specified in section 25, or a wall anchored to, and restrained by, roof-trusses or a roof or roof-components, to the satisfaction of the local authority;

c) “a wall moderately restrained at the top” means a wall supporting a timber floor, and anchored to it as specified in section 25, or a wall anchored to, and restrained by, roof-trusses or a roof or roof-components, to the satisfaction of the local authority;

“roof”-

a) “flat roof” means a roof which is not a pitched roof;

b) “heavy roof” means a roof construction including framing, purlins and covering, having a mass of more than 35 kilograms per square meter of horizontal area;

c) “pitched roof” means a roof supported on the external walls of the building;

“rubble”-

a) “random rubble” means masonry composed of roughly shaped or unshaped stones laid without regularity or coursing;

b) “squared rubble” means masonry composed of roughly squared stones arranged to form well-defined horizontal joints;

“sleeper-wall” or “sleeper-pier” means a foundation-wall or pier erected between other foundation-walls or -piers to provide an intermediate support to the lowest floor, and having no corresponding wall or pier directly above it;

“slenderness ratio” means a ratio between the dimensions of a wall or a column, as prescribed by subsections (1) and (2) of section 66, which is used in determining the permissible stresses;

“soil-cement” means a mixture of natural soil and cement compacted, when moist, into a structural material;

“strength” of a building-unit or material means the average strength of a sample of the unit or material measured as specified in the relevant specification or, if there is no specification applicable, as described by testing authority;

“thickness”, applied to a wall, means the actual thickness;

“effective thickness of a wall” means the thickness of a wall assumed for calculating its slenderness ration, as set out in subsections (5) to (10) of section 66;

“veneer” means the facing attached to a veneered wall;

“heavy veneer” means a veneer having a mass of not less than 75 kilograms per square meter, exclusive of the backing-mortar;

“light veneer” means a veneer having mass of less than 75 kilograms per square meter, exclusive of the backing-mortar;

“masonry veneer facing” means a veneer facing composed of masonry building units;

“wall”-

a) “balustrade-wall” means a wall erected in place of a balustrade and serving the same purpose;

b) “basement-wall” means an external wall of a building, enclosing usable floor space of a basement and either wholly or partly below ground-level;

c) “bearing-wall” means a wall which supports any vertical load in addition to its own mass and the mass of a veneer;

d) “cavity-wall” means a wall in the form of two walls(called leaves), built side by side, tied to each other, and separated by a cavity, either left open as an air space or filled with non-loading material;

e) “cross-wall” means an intersecting, bearing or non-bearing wall which may be considered to limit the unsupported length of the wall which it intersects;

f) “curtain-wall” means a non-bearing external masonry wall of a height of one or more than one storey, and which is laterally supported, either by piers or by the vertical and horizontal structural members of the frame of a building, and may be supported over part of its thickness on the slabs or the beams of such frame, and which carries no load other than its own mass and the mass of veneer, if any, and resists and no force other than wind force;

g) “external wall” means a wall separating the interior from the exterior of a building;

h) “faced wall” means a wall in which a facing and a backing are intended to exert a common reaction under load, and are built up simultaneously;

i) “foundation-wall” means a bearing-wall situated below the lowest floor-level;

j) “free-standing wall” means a wall without adequate lateral support at either end or along the top;

k) 32 times its effective thickness;

l) “non-bearing -wall” means a wall which supports no vertical load other than its own mass and the mass of veneer, if any;

m) “panel-wall” means a non-bearing external wall, built between columns, walls or piers, and not exceeding one storey in height;

n) “parapet-wall” means a wall, or that part of a wall, which is entirely above the abutting upper surface of the roof;‘ “internal-wall” means a wall wholly within a building;

o) “masonry breast-wall” means a masonry wall, or portion of such wall, which extends from the floor on which it is built to the sill of a window, and which extends for a length greater than

p) “partition-wall” means a non-bearing internal wall, which is employed solely for the purpose of subdividing any storey of a building of a building into sections;

q) “retaining-wall” means a wall intended to resist the lateral displacement of materials other than liquids;

r) “rubble stone wall” means a wall constructed of random rubble or squared rubble;

s) “skin wall” means a wall protecting a vertical waterproof or damp-proof layer;

t) “sleeper-wall” see “sleeper-wall” or sleeper-pier;

u) “solid wall” means a wall other than a cavity wall;

v) “veneered wall” means a wall which has a facing and a backing which are not intended to exert a common reaction under load;

w) “wing-wall” means a wall which has adequate lateral support at one end only;

“0,3 per centum proof stress” means the tensile stress at which a non-proportional elongation equal to 0,3 per centum of its original length occurs in a material under load.

2.INTEPRETATION OF CERTAIN TERMS.

(1) Wherever “resist” or “sustain” occurs in Chapter, it shall mean resist or sustain, as the case may be, at the stresses permitted in this Chapter.

(2) Wherever “wall” or “walls” occurs, it shall not mean a veneered wall or walls, unless stated to the contrary.

(3) Wherever the thickness of a wall is mentioned, it shall mean the actual thickness, unless the effective thickness is stipulated.

3.DIMENSIONS SUBJECT TO TOLERENCES.

Where the minimum dimension of a wall, a pier or column built of masonry is given in millimetres in this Chapter, then, to make allowance for the tolerance permitted in the size of the standardized building-units, such minimum dimension shall be deemed to be subject to the tolerance set forth in Table I.

TABLE I

DIMENSIONS SUBJECT TO TOLERANCES.

| 1 | 2 |

| Dimensions in millimeters | Tolerence (minus) in millimetres |

| 50 65 100 215 or greater | 3 3 3 5 |

4.APPLICATIONS OF REGULATIONS TO MANSORY AND CONCRETE WALLING.

(1) All buildings composed of masonry construction, and all masonry and concrete walls, shall be erected in accordance with the provisions of this section.

(2) All materials and building-units shall comply with the requirements of section 5.

(3) The construction shall be executed in accordance with the general requirements of sections 6 to 38, and, in addition, every part of the construction shall be constructed either-

a) in accordance with the general requirements for empirical construction set out in sections 39 to 43, and the particular requirements for empirical construction set out in sections 44 to 62, applicable to the building-units or materials used; or

b) in accordance with the provisions of sections 63 to 82 for the calculated designed masonry construction:

Provided that-

i) where no calculations are submitted for approval in connexion with the design of any masonry building, or any particular portion of such building, it shall be assumed that such building or portion is intended to comply with the requirements for empirical construction set out in 39 to 62; and

ii) the local authority shall be entitled to require that-

A. walls and piers which support any cantilevered load other than the loads from lintels or from timber floor-joints or ceiling-joists, or from timber rafters or trusses; and

B. any portion of the building which the local authority considers would otherwise be dangerous;

shall either be designed in accordance with the provisions of sections 63 to 82 for the calculated design of masonry construction or be constructed of other materials in accordance with these by-laws.

(4) All walling of materials other than masonry or concrete shall comply with the requirements sect out in section 7 for unspecified materials’

5.REQUIREMENTS FOR MATERIALS AND BUILDING-UNITS.

(1) Materials not provided for in these by-laws.- Subject to the provisions of section 7, building materials not provided for in these by-laws may be used in walling if they comply with the terms of a departure certificate or authorization granted in terms of Part VII of Chapter 2.

(2) Second-hand materials.- Second-hand building materials may not be used unless such materials-

a) are sound; and

b) comply with the requirements of these by-laws; and

c) have been thoroughly cleaned and all adhering other materials which would interfere with their intended function removed.

(3) Cement.- Cement used in masonry shall comply with the requirements of C.A.S. No. A46:

Provided that cement not so complying, but, nevertheless, complying with a specification acceptable to the local authority, may be used.

(4) Lime.- Lime used in masonry shall comply with the requirements of C.A.S. No. A15, Building limes.

(5) Fine aggregate(sand).- Fine aggregate used in mortar shall comply with the requirements os C.A.S. No. A34, Aggregates for concrete, and, in addition-

a) at least 97 per centum of any sample measured by mass, shall pass tthrough a 2,36 millimetre sieve; and

b) the percentage which passes a 75-micrometre sieve when tested in accordance with C.A.S. No. A33, Methods for sampling and testing of minerals aggregates, sands and fillers, shall not exceed 7,5 per centum.

(6) Fine aggregate in concrete shall comply with the requirements of C.A.S. No. A34

(7) Water.- Water for use in masonry or concrete walling shall be clean and free from clay and silt and such amounts of oil, acid, alkali or organic or other matter as, in the opinion of the local authority, will seriously impair the strength and durability of the masonry or walling

(8) Coarse aggregate (stone) .- Coarse aggregate for concrete shall comply with the requirements of C.A.S No. A34.

(9) Standard building units .- The building-units listed in this subsection, when used in construction of buildings, shall comply with the requirements of the standard specification application to the unit concerned, and, in addition, shall comply with the other provisions of this Chapter.

Table

(10) Hollow glass blocks which are 298, 5 millimetres square in elevation, but which in other respects comply with B.S. 1207, shall also be permitted.

(11) Stone for masonry.- Rubble stone shall have a “crushing value” (10 per centum fine test) when tested in accordance with C.A.S No. A33 of not less than 75 kilonewtons.

(12) Soil-cement blocks and bricks.- Soil-cement blocks and bricks, when tested in accordance with C.A.S No. 41, shall comply with the following requirements-

a) the average compressive strength at an age of 28 days shall not be less than 2,8 megapascals;

b) the increase in mass after immersion in water for 24 hours shall not exceed 12 per centum of the dry mass;

c) the linear expansion after immersion in water for 24 hours shall not exceed –

i) 0,05 per centum where, in the opinion of the local authority, cracking of the walls cannot be tolerated;

ii) 0,1 per centum where the blocks or bricks are to be used only in internal walls.

6.EXTERNAL WALLS TO BE WEATHERPROOF.

(1) Every external masonry or concrete wall of a habitable portion of a building shall be capable of withstanding the artificial rain test described in the Second Schedule and shall be-

a) constructed of masonry building-units so as to be at least 200 millimetres thick; or

b) constructed of plain normal concrete at least 200 millimetres thick or reinforced concrete at least 100 millimetres thick, and be treated if necessary; or

c) constructed of no-fines concrete at least 200 millimetres thick; or

d) of such lesser thickness as is permitted by this Chapter for the relevant conditions.

(2) Every external wall of a habitable portion of a building which is not of masonry or concrete shall be weatherproof to the satisfaction of the local authority.

7. WALLING OF UNSPECIFIED MATERIALS.

(1) For the purposes of this section –

“structural damage” shall mean a cracking, spalling or crumbling of the surface of the wall which is readily visible to the naked eye. The fracture of glass in adjacent windows or damage to applied finished shall not be deemed to be structural damage to the wall;

“structural failure” shall mean collapse of the wall or a portion of the wall, or holding of the wall;

“load factor” shall mean the quotient found when that load which causes the first signs of structural damage or structural failure, as the case may be , is divided by the maximum load which the walls are designed to support.

(2) If the walls of a building are to be constructed of materials or building-units not specified in this Chapter, the local authority may call for tests to be conducted, or a report submitted, according to the provisions of Chapter 2, and shall prohibit the use of such materials or units unless the results of the tests demonstrate or the report shows, that such walls comply with such of the following requirements as are, in the opinion of the local authority, applicable to them-

a) when loaded with static loads, the walls shall provide load factors for structural damage and for structural failure not less than those considered satisfactory by the local authority for the material and method of construction concerned;

b) the walls shall withstand the impact test set out in the First Schedule;

c) the deflection, under design load, at the center of walls which are to be plastered shall not exceed 1/360 of the distance between lateral supports, and that of walls which are not to be plastered shall not exceed 1/240 of such distances;

d) when testes for moisture penetration as described in the Second Schedule, walls shall not show visible dampness on the inside surface to the extent specified within a lesser period than set out in the Table in that Schedule for the appropriate conditions;

e) the construction shall be shown to be, or be assessed as being

i) durable; and

ii) stable under variations in load, and under variations in temperature and moisture content which are due to climatic conditions.

8. SUPPORT OF WALLS.

(1) Every wall supported by another all or a structural member shall be supported on a foundation complying with the provisions of Chapter 4, except where the local authority permits the construction of a wall on solid rock after having satisfied itself that the safety of the building will not be endangered by the omission of a foundation.

(2) Except as provided in section 21, no wall shall be allowed to carry a wall thicker than itself, and where, in a building, walls are interrupted by floor-slabs, every wall in each storey shall be located vertically over the wall below, unless full provision is made in the design of such building to support a wall in another position.

(3) Lateral stability to a building as a whole shall be provided by cross-walls or by other means which are to the satisfaction of the local authority.

(4) Empirically constructed walls other than wing-walls, free standing walls and retaining-wall shall have adequate lateral supports at each end.

(5) Empirically constructed external walls shall be either moderately or fully restrained at the top in each storey of a building.

(6) Empirically constructed gable-walls shall be securely anchored to the roof along the top of the gable, and, where necessary, in the opinion of the local authority, provision shall be made at such anchorage to accommodate movement of the roof due to expansion or contraction of the roof.

9. LOADING OF MANSORY MEMBERS.

(1) Where floor-slabs or other slabs or beams are supported by masonry or plain concrete walls, piers or columns, no loads other than the normal surface finishes shall be superimposed upon such supporting members, unless adequate falsework is left or placed under them to carry such superimposed loads without undue deflection, until-

a) such time as the mortar or concrete in such walls, piers or columns has attained the minimum comprehensive strength at 28 days applicable to the class of mortar or concrete employed, as specified in section 13 or 14 respectively; or

b) failing tests to demonstrate such strength referred to in paragraph (a), the following periods have elapsed after the mixing of the mortar or concrete used in the last portion of such walls, piers or columns to the constructed-

i) for class D mortar, 28 days;

ii) for other mortar and concrete made with-

A. Portland cement other than high early strength Portland, 28 days;

B. high early strength Portland, cement, 5 days.

TABLE II

LOADING OF MANSONRY MEMBERS

cementitious materials

| 1 | 2 |

| PERIOD | MAXIMUM HEIGHT OF FILL |

| Less than 3 days 3 days the required period | One third full height as specified in section 46. Full height |

“full height” means the height of fill for which a wall acting as a retaining wall has been designed, or, for an empirically con structed foundation or basement wall, means the height specified in section 46 for such brick foundation or basement walls;

† required period” means-

(a) the period required to achieve the design strength of the mortar or concrete or the required strength thereof as set out in section 13 or 14, as the case may be; or

(b) the period set out above in this section for the class of mortar or concrete concerned, before walling supporting slabs or beams is permitted to receive its full load;

whichever is the lesser.

(2) Fill or back-fill shall not be placed against any wall until the period set out in Table II for the relevant maximum height of fill has elapsed after the completion of the wall.

10. LOAD-BEARING SURFACING.

(1) Except as specified in subsection (2), all building-units in masonry construction shall be laid in horizontal courses with their load-bearing surfaces horizontal.

(2) The exceptions to subsection (1) are-

a) stones in random rubble stone walls;

b) stones in natural stone bearing-walls, in which case the beds of the stones shall be approximately level for a minimum distance of 120 millimetres back from the face of the wall;

c) building-units which are permitted to be built to a pattern not forming horizontal courses:

Provided that, for the purposes of section 17, the portion of the wall formed by such units shall be regarded as either an opening or a recess, depending on whether or not such portion extends to a thickness greater than one third of the thickness of the wall;

d) cases where the local authority is satisfied that the design requires the bedding-planes to be inclined to the horizontal.

11. BOND

(1) Except in rubble stone wall, the vertical joints in successive courses in masonry walls shall break joint to the extent of at least a quarter of the length of a building-unit.

(2) Whenever the thickness of a solid wall of bricks or blocks is composed of more than one building-unit, either wall ties shall be built into such a wall to bond it together or a bond shall be

employed which provided a complete course of headers evenly distributed over the face area of the wall.

(3) The clear distance between any header or tie and its nearest neighbor in any direction in any direction shall not exceed the following value-

a) for bricks-

i) 450 millimeters, measured vertically; or

ii) 900 millimeters, measured horizontally;

b) for blocks-

i) 600 millimeters, measured vertically; or

ii) 900 millimeters, measured horizontally.

(4) Where wall-ties are employed to bond together the leaves of a wall, both the ties and their spacing shall comply with the requirements of section 33, whether the leaves are separated by a cavity or not.

(5) Bond-stones.- In walls built of natural stone, bond-stones shall be evenly distributed over the face areas of the wall, and shall be provided on both sides to such an extent that the area of the bond-stones on each side, measured in the plane of the wall, is not less than one-sixth of the face area of the wall.

(6) The bond-stones referred to in subsection (5) shall, in the case of rubble stone walls, which are not retaining-walls, be built into the thickness of the wall to a depth of not less than 320 millimeters or the thickness of the wall, whichever is less, and, in the case of rubble stone retaining-walls, the bond-stones shall extend far enough from each face into the thickness of the wall to overlap the adjacent bond-stones extending from the opposite face by not less than 100 millimeters.

(7) In the case of ashlar masonry walls, bond-stones shall extend throughout the full thickness of the wall.

(8) The maximum distance between adjacent bond-stones on the same side of the wall, center to center, in both the horizontal direction and the vertical stone walls not more than 600 millimeters thick and 750 millimeters for rubble stones walls thicker than 600 millimeters.

(9) Walls shall be properly bonded by a masonry bond to piers and buttress, and, except where walls are bonded to cross-walls by anchors in accordance with section 19, to cross walls.

12. WORKMANSHIP.

(1) Except where the local authority considers it to be unnecessary or inadvisable, all walls shall be plumb, and shall be adequately braced during construction.

(2) Except for concrete and soil-cement building-units, which shall be kept in a dry condition, all masonry building-units shall be thoroughly wetted with water immediately before being laid.

(3) Except in rubble stone walls, and where permitted by the local authority, all masonry building -units shall be laid in mortar joints shall be filled, and shall be not less than 5 millimetres and not more than 20 millimetres in thickness.

(4) No portion of a masonry wall shall be built up during building operations more than 1 metre above the top of any other portion of such wall.

13.MORTARS.

(1) Mortars: classification.-Except where gypsum is required by section 36, or where another mortar is permitted under subsection (8) , mortar shall be one of the classes specified in Table III to subsection (7), and shall otherwise comply with the requirements of this section relating to its class. The requirements of this section relating to its class. The use of “artificial plasticisers” may be employees as an additive to cement mortars with the approval of the local authority.

(2) Composition: class A.- Class A mortar shall be composed of Portland cement together with fine aggregate in the proportions specified in subsection (7) . Plastic hydrated lime to the extent of no

more than 25 per centum of the dry cement by volume may be added to increase the workability, Such mortar shall be used within 60 minutes of the time when the cement was added to the mix.

(3) Composition: classes B and C.- Classes B and C mortars shall be composed of Portland cement together with fine aggregate in the proportions specified in subsection (7), and may include either lime-putty or hydrated lime.

(4) If normal lime is used in class B or class C mortar-

a) the mortar shall not be used as before it has been allowed to mature for at least 24 hours after the lime has been mixed with the fine aggregate; and

b) the mortar shall be used within 60 minutes of the time when the cement was added to the mix.

(5) Composition: class D.- Class D mortar shall be composed of lime-putty or hydrated lime and fine aggregate in the proportions specified in subsection (7), and Portland cement to the extent of not more than 25 per centum by volume of the dry lime may be added to increase the strength.

(6) If normal lime is used in class D mortar, the mortar shall be allowed to mature before being used for at least 24 hours after the lime has been mixed with the fine aggregate.

(7) Proportions and required strength mortars.- When tested in accordance with the Third Schedule, mortars of the classes specified in Table III shall have the minimum compressive strength shown in that Table.

TABLE III

MIXING PROPORTIONS AND STRENGTHS OF MORTARS

| 1 | 2 | 3 | 4 | 5 |

| LIMITING PROPORTIONS MEASURED BY VOLUME | Minimum required compressive strength in megapascals (at 28 days) | |||

| Class | cement | lime | fine aggregate | |

| A B C D | 1 1 1 0.25 | 0-0.25 0-1.25 0-2.5 1 | not more than 4 not more than 6 not more than 9 not more than 4.5 | 14.0 6.5 2.0 0.6 |

(8) Special mortars.- Mortars other than those specified in subsection (1), such as hydraulic lime mortar, may be used where tests have shown them to be satisfactory with regard to strength, soundness and consistency, to the satisfaction of the local authority.

(9) Permitted use of mortars.- Except where the provisions of this Chapter require otherwise, mortars shall be used only as specified in subsections (10) to (13):

Provided that mortar classes of a higher required compressive strength may be used for the purposes permitted for a class of lower required strength, but not vice versa.

(10)Class D mortar may be used-

a) in a bearing-wall or pier in a single storey building, or in the topmost storey of a building:

Provided that-

i) such wall shall not be a cavity-wall or a rubble stone wall; and

ii) such mortar shall not be used in a portion of the wall which is either above the surface of the roof or below the damp-proof course near ground-level or which is exposed to continual dampness;

b) in a partition-wall or a curtain-wall or a panel-wall, but not in a retaining-wall or a balustrade-wall or a free-standing wall.

(11) Class C mortar may be used-

a) in a bearing-wall pier:

Provided that such mortar shall not be used in a portion of the wall which is either above the surface of the roof or below the damp-roof course near ground-level, or which is exposed to severe conditions of continual dampness;

b) in a partition-wall or curtain-wall or a panel-wall, but not in a retaining wall or a balustrade-wall.

(12) Class B mortar may be used in bearing-walls, piers and columns, and in partition-walls, curtain-walls, panel-walls, free-standing walls and wing-walls.

(13) Class A mortar may be used in any masonry construction.

(14) Gypsum mortar.- Gypsum mortar shall composed of gypsum and fine aggregate, the volume of which shall not exceed twice that of the gypsum.

(15) In no case shall gypsum be mixed with Portland cement, or be allowed to come into contact with Portland cement or the products thereof within seven days of the time when Portland cement was mixed with water.

(16) Gypsum mortar shall not be used as mortar with building-units other than gypsum or glass blocks:

Provided that it may be used as internal plaster with any mature building units.

14. CONCRETE IN WALLING.

(1) Concrete used in walls, piers and columns, and in foundations for them, shall except where otherwise specified, be made, placed and cured in accordance with the requirements of the appropriate Central African, and, in addition, shall comply with requirements of the of the following subsections.

(2) Normal concrete, other than light-mass concrete used in the construction of load-bearing members, shall be mixed in the proportions of one part of cement to not more than nine parts in all, when measured by volume and counted separately before mixed, of fine and coarse aggregate, and such concrete used in the construction of non-load-bearing members shall be mixed in the proportions of one part of cement to not more than than twelve parts in all of fine and coarse aggregate, measured in the same way.

(3) Light-mass concrete and no-fines concrete used in bearing-walls shall be made, placed and cured in accordance with the requirements for controlled concrete in Chapter 3.

(4) When tested in accordance with the provisions of Chapter 3, the various classes of concrete shall have a cube strength at an age of 28 days of not less than the following-

a) normal concrete, with ordinary aggregate-

i) for load-bearing members, 14 mega pascals;

ii) for non-load-bearing members, 7 mega pascals;

b) light-mass normal concrete, 3,5 mega pascals;

c) no-fines concrete employing ordinary aggregate, 2,45 mega pascals;

d) no-fines concrete employing light-mass aggregate, 1,75 mega pascals.

1Note that further requirements are set out as follows-

for reinforced-concrete walls and columns, in section 74;

for reinforced-concrete lintels, in section 18;

for unreinforced-concrete walls, in sections 61, 62 and 70.

15.CONSTRUCTION IN COLD WEATHER.

No masonry construction shall take place when the temperature at the site of work is below-

a) 2 degrees Celsius at a time when the temperature is rising; or

b) 5 degrees Celsius at a time when the temperature is falling.

16.USE OF EXISTING MANSONRY .

(1) an existing masonry wall, pier or column may be used in the construction of a building, and in the repair, alteration or enlargement of a building, if it complies with the requirements of these by-laws.

(2) an existing masonry wall which is structurally sound which is of insufficient thickness for its proposed use may be made thicker by the addition of material similar to that of the existing wall, laid in mortar of the required proportions, if the foundations for the completed structure comply with these by-laws.

(3) The additions or linings referred to in subsection(2) shall be thoroughly bonded to the existing masonry by toothings bonded 100 millimeters deep or the full thickness of the lining. Whichever is lesser, into the new masonry, and at least 100 millimeters into the existing masonry.

(4) The toothings referred to in subsection (3) shall be distributed uniformly throughout the area of the additions to the wall, and shall have an aggregate vertical cross-sectional area not less than 15 per centum of the total area of that part of the wall thickened by lining.

(5) Plaster, or adherent coatings which might impair the adhesion shall be stripped off any wall-surface against which a lining is to be built, and the whole of such masonry surface shall be created before the construction of the lining is commenced.

17. OPENINGS, CHASES AND RECESSES.

(1) Lintels and arches over openings2..-The portion of a masonry or concrete wall above an opening shall be provided with a lintel constructed as an arch, and shall comply with requirements as set out in Chapter 3 or section 18.

(2) Chases and recesses.- Where horizontal chases or recesses are cut to a depth greater than one-fifth of the thickness of the wall, or leaf of the cavity-wall, concerned, or are built into the wall to a depth grater than one-third of such thickness, or where chases or recesses are cut or formed on both sides of particular length of wall, then such chases of section 40, and shall be bridged over accordingly.

(3) Decorative timber or timber nailing-strips may be set into masonry or concrete walls, piers or columns, but such timber is regarded as a recess if the depth of building is less than one-third of the thickness of the wall, and as an opening if it is more than one-third.

(4) No length of wall between openings which is less than 230 millimetres in length shall have any openings, recess or chase out into it unless supported to the approval of the local authority:

Provided that this provision shall not be constructed as preventing such an opening, recess or chase being built in as construction proceeds in such a length of wall.

(5) Every chase shall be filled solidly around services with mortar not weaker than class B, and the filling shall be allowed to harden before any plastering is done. The surface of the chase shall be wetted down and the mortar made dry around service-boxes shall be similarly filled with mortar not weaker than class B.

(6) Wall not to be endangered by openings, chases or recesses.- The number, size, position and manner of forming of openings, recesses and chases in any masonry or concrete wall such that such wall, pier or column is not, in the opinion of the local authority, thereby rendering unsafe.

18. LINTELS.

(1) Reinforced concrete lintels may:-

a) be constructed in accordance with the requirement set out in the Fourth schedule: or

b) be proprietary pre-cast lintels of approved manufacture.

(2) Lintels of types other than that specified in subsection (1) may be used to the design and construction being approved by the local authority.3

2 Where required by the provisions of Chapter 11, lintels should have the fire-resistance rating there specified for structural members.

3Reinforced brick lintels, if designed and constructed to accord with the provisions of NBR1 Information sheet X/BOU 2-29, dated June 1975, issued by the National Building Research Institute of South Africa, shall be deemed to satisfy the requirements of the local authority.

19. CROSS WALLS.

Every cross-wall shall comply with the follow- ing requirements-

(a) it shall be built at an angle of not less than

40 degrees with the wall which it intersects;

Where required by the provisions of Chapter 11, lintels should have the fire-resistance rating there specified for structural members.

“Reinforced brick lintels, if designed and constructed to accord with the provisions of NBRI Information Sheet X/BOU 2-29, dated June, 1975, issued by the National Building Re- search Institute of South Africa, shall be deemed to satisfy the requirements of the local authority.

(b) it shall be carried up to the full-storey height of the wall which it supports;

(c) if a gable is to be supported laterally by a cross-wall, the wall may be raked up to the gable in the form of a buttress commencing from the top or wall-plate level of the wall: Provided that-

(i) the angle of the rake is not greater than 45 degrees to the horizontal; and (ii) the height of the buttress shall be designed to provide the maximum necessary support to the gable at a point where the cross-wall meets the gable-face; and

(iii) the cross-wall and the buttress shall be bonded to the gable.

(d) its over-all thickness shall be not less than 200 millimeters for solid walls or 280 millimeters for cavity-walls:

Provided that, in a single-storey building or the topmost storey of a building, the over- all thickness may be 100 millimeters for solid walls or 200 millimeters for cavity-walls; (e) the unbroken length of the cross-wall, adjoining the supported wall, shall be not

less than-

(i) for cross-walls less than 200 millimeters in thickness, one-third of the height of the walls; and

(ii) for cross-walls not less than 200 millimeters in thickness, one-quarter of the height of the walls;

(f) the length of cross-walls which are wing- walls or portions of intersecting walls shall be measured from the nearer face of the supported wall, excluding the thickness of the latter;

(g) where a cross-wall is bonded into two return walls, extending in opposite directions from the two ends of the cross-wall, the length of the cross-wall shall include the thickness of the two return walls;

(h) a cross-wall shall be deemed to be properly bonded to a cavity-wall if it is bonded to one leaf only:

(i) a cross-wall which is a cavity-wall shall have both leaves bonded to the wall which it, supports;

(j) when a wall and the cross-wall supporting it are built up separately-

(i) the wall and cross-wall shall be bonded together by regular and evenly spaced toothing’s comprising half the height of the walls, so as to provide a bond of not less than 100 millimeters; or

(ii) metal anchors of minimum cross- section 3 x 32 millimeters or of equivalent cross-sectional area and at least 450 millimeters in length, with ends bent up at least 50 millimeters, shall be provided at vertical intervals not exceeding one meter, and such anchors shall be protected against corrosion.

20. THRUST FROM THE ROOF.

(1) Where a roof exerts lateral thrust on supporting walls, piers or columns which results wholly or partly from dead, the walls, piers or columns shall be designed in accordance with requirements of sections 63 to 82.

(2) If such thrust results from superimposed load only, then no such design shall be necessary on that account.

21.CORBELLING.

(1) Walls less than 215 millimetres in thickness shall not be corbelled, nor, in a cavity-wall, shall a leaf less than 215 millimetres in thickness corbelled :

Provided that nothing in this section shall be construed as preventing walls overhanging their supports in accordance with the provision of section 22.

(2) In a single-storey dwelling-house or dwelling-units, a 215 millimetres solid foundation-wall may be corbelled to support a cavity-wall of a maximum over-all thickness of 300 millimetres:

Provided that –

i) the total projection does not exceed 50 millimetres on either side;

ii) the foundation-wall is corbelled out to provide a solid bearing of the full total thickness of the cavity-wall in accordance with section 22;

(3) Except as may be permitted in the requirements for constructions specified in Chapter 22, and as set out in this section, no corbel shall be used to support wall.

(4) No corbel from a masonry less than 330 millimetres in thickness shall be used to support a floor or a roof, except that, in dwellings-houses or dwelling-units only, wall not less than 215 millimetres in thickness may be corbelled to support a timber floor.

(5) Walls built of hollow building-units shall not be corbelled.

22. OVERHANGING WALLS.

Walls may overhang their supports only in the case of a single-storey building or the top storey of a building:

Provided that-

i) the base of a solid wall or of the leaf of a cavity-wall shall not overhang its support to a total extent greater than one-third of its thickness, whether the overhang occurs on one or both sides;

ii) a cavity-wall which is built up a solid wall, properly bonded, to a height above its base of not less than its total thickness, shall not overhang its support to a total extent greater than one-quarter of its total thickness;

iii) the support for the overhanging portion of the solidly built-up base of a cavity-wall shall be a corbel, in which each individual course projects beyond the course below by not more than one-third of the height of the course

or, alternatively, shall be a further portion of solid wall, properly bonded, equal in height of a corbel constructed as described in this section.

23. CORNICES.

The center of gravity of every cornice, whether surmounted by masonry or not, shall fall within the middle third of the thickness of the wall below, unless adequate structural support is provided.

24. END OF BEAMS AND RAFTERS.

(1) Solid bearing-walls less than 215 millimeters in thickness, and cavity bearing-walls having both leaves not thicker than 100 millimeters each, shall not be broken into, subsequent to being built, for the insertion of beams or rafters, except with the written approval of the local authority.

(2) Timber beams and joists supported upon masonry shall have a bearing at least 75 millimeters in length at each point of support.

(3) beans and girders, other than loose of timber, in empirically constructed buildings shall have an area of bearing masonry in accordance with the provisions of section 41.

(4) In buildings not empirically constructed, the bearings shall be such as yo prevent stresses in the masonry exceeding those specified in sections 63 to 73 or in section 78.

25. ANCHORAGE TO JOISTED TIMBER AND PRECAST CONCRETE FLOORS.

(1) Where the joisted timber or precast concrete floors are to be regarded as providing lateral restraint to the supporting-wall at the level of the floor, anchors shall be provided to secure the bearers or joists or flooring-units to the wall at distances apart not greater than 1,8 metres, measured along the wall extending through two storeys, or not greater than 1,2 metres for a wall extending through more than two storeys.

(2) The anchors referred to in subsection (1) shall-

a) be of corrosion-resistant metal or protected metal; and

b) have a cross-section of not less than millimetres, or equivalent area; and

c) have a length of not less than 600 millimetres; and

d) be securely fastened to timber joists by screws, nails or bolts; and

e) be anchored in the wall by means of split and upset ends, or by other effective means.

(3) Where the restrained wall is parallel to timber joists, such anchors shall be secured to not less than three joists with fastenings which can develop the full strength of the anchor, and herring-bone or solid strutting of cross-section not less that 38 x 38 millimetres shall be provided between three joists nearest the wall.

(4) The strutting referred to in subsection (3) shall be at right angle to the joists and opposite the wall-anchor.

(5) Where such a wall is parallel to precast flooring-units –

a) the anchors shall be carried over at least three supporting units or extend at least 750 millimetres from the wall; and

b) the ends shall be turned down at least 50 millimetres between units or into in situ concrete ribs; and

c) such anchors shall be protected from corrosion by a dense cement-mortar topping not less than 25 millimetres in thickness.

(6) In the case of cavity-walls, such anchors need to be fixed in the nearer leaf only.

26. RETAINING-WALLS: GENERAL.

(1) Every retaining-wall which does not comply with the provisions of section 46 or 46 shall be designed in accordance with the requirements of section 63 to 82.

(2) A French drain or other efficient form of drain shall be provided behind a wall over 400 millimetres in height, intended to act as a retaining -wall, to drain fill, and steps shall be taken, where needed, to prevent erosion of the fill near the drain.

(3) weep-holes to carry off water from such drain shall be provided through such a wall, of size and spacings suitable in the opinion of the local authority, for the soil conditions prevailing.

(4) A surface-drain shall be provided in front of the retaining-wall to dispose of water from the weep-holes.

(5) Notwithstanding the provisions of subsections (2) to (4), the local authority may approve other similarly adequate means to drain the fill behind the retaining-wall, and to dispose the water so drained off.

27. PARAPET-WALLS, BALUSTARDE-WALLS AND BREAST-WALLS.

(1) Masonry parapet-walls shall be designed in accordance with the requirements of section 63 to 82, unless they are bonded into return walls bonded to the structural frame of the building, or are tied to reinforced-concrete or reinforced-brick columns, or bonded into reinforced-brick piers.

(2) Reinforced-concrete columns shall be constructed in accordance with the provisions of Chapter 3.

(3) Reinforced-brick columns and piers shall comply with the requirements of sections 75 to 82.

(4) The return walls, columns and piers referred to in subsection (1) shall be no farther apart, center to center, than-

a) 7,5 meters for parapet-walls 215 millimeters in thickness; or

b) 4,5 meters for parapet-walls 100 millimeters in thickness

(5) If masonry parapet-walls are constructed on a concrete slab, they shall be provided with expansion joists at distances apart not exceeding 7,5 meters, and if such walls are bonded to piers, the expansion joints shall bisect the piers.

(6) Empirically constructed parapet-walls shall be constructed in accordance with section 53, and, if such walls act as balustrades, they shall comply with the requirements of subsection (7).

(7) Masonry balustrade-walls shall be designed in accordance of sections 63 to 82, unless tied columns or bonded into return walls or piers, and shall be provided, where necessary, with expansion joints as required for parapet-walls by subsection (5):

Provided that the return walls, columns or piers shall be not farther apart than-

a) 6,6 meters for a wall 215 millimeters in thickness; or

b) 4,05 meters for a wall 100 millimeters in thickness;

and the expansion joints shall not be farther apart than 8,1 meters.

Attention is drawn to the requirements for balustrades in Chapters 11 and 12.

28. VENEERED WALLS.

(1) Materials used as veneers shall have a thickness not less than stated in S.A.B.S. 073 except where the local authority permits a local diminution of thickness such as required to permit the support of veneer on a rib, slab or beam.

(2) Materials used for masonry veneer shall be sound and durable and free from fissures which might affect their durability, and, in the opinion of the local authority, have a record of satisfactory use under conditions comparable to those of their intended use, or be proven durable under test conditions comparable to exposure in the place of their intended use.

(3) No materials other than those referred to in S.A.B.S. 073 shall be used for anchors unless they are tested and shown to be satisfactory, in the opinion of the local authority.

(4) The thickness of the veneer shall not be included in the required thickness of veneered walls. The thickness of the backing and the height of the veneered walls shall be-

a) for empirically constructed walls, as set out in sections 42 and 43;

b) for designed walls, as required by sections 63 to 82

Provided that due allowance shall be made for the additional load caused by the mass of the veneer, and that effective thickness of the wall is derived from the thickness of the backing alone.

(5) Veneer faces shall be designed and constructed in accordance with the requirements of S.A.B.S 073, unless calculations of stresses are submitted to, and approved by the local authority.

(6) Heavy masonry veneer facings shall be tied into a backing of masonry or other non-combustible material5 which is, in the opinion of the local authority of adequate stability and rigidity.

(7) Light masonry veneer facings shall be provided with supports at the heads of all openings, except where the omission is specifically approved by local authority.

(8) The use of veneers shall otherwise comply with the requirements of S.A.B.S. 073.6

5 Attention is drawn to the fact that masonry veneer facings which are fixed direct to the structural framework must comply with the requirements for curtain-walls or panel-walls(see definition)

6The sealing-coat and mastic should preferably be from the same manufacturer.

29. FACED WALLS.

(1) For empirically constructed faced walls the building-units and mortar comprising both facing and backing shall comply with the requirements of section 42.

(2) No materials other than those referred to in S.A.B.S. 073 shall be used for anchors unless they are tested and shown to be satisfactory, in the opinion of the local authority.

(3) When the thickness of a faced wall is derived from calculation, the permissible stresses applicable to the building-units and mortar forming the facing or those forming the backing (whichever gives the greater thickness of wall) shall be applied to the whole of the wall.

(4)When the thickness of such wall is taken from the requirements of this Chapter for empirically constructed walls, such thickness shall be that applicable to the building-units and mortar comprising the backing or to those compromising the backing or those comparing the facing, whichever building-units and mortar require the greater thickness.

(5) The use of facings in faced walls shall otherwise comply with the requirements of S.A.B.S 073.

30.MASONRY CURTAINWALLS.

(1) Masonry curtain-walls shall be tied to the horizontal and vertical structural members of the building frame by means of corrosion-resistant anchors, which are secured to such members with fastenings which develop the full strength of the fastenings which develop the full strength of the anchor, and there shall be at least anchor for each 0,8 square metre or remaining portion thereof of face-area of the curtain wall, and anchors shall be evenly spaced along such members.

(2) The anchors referred to in subsection (1) shall have the minimum dimensions set out in Table IV.

TABLE IV

ANCHORS FOR CURTAIN-WALLS

| 1 | 2 | 3 |

| Minimum size in millimeters | ||

| material | wire anchors (diameter) | strip anchors (thickness x width) |

| copper hard drawn…….. annealed……….. brass 70% copper 30% zinc annealed……… half hard ……. stainless steel mild steel, galvanised or otherwise adequetly protected malleable cast iron adequetly protected | 4,00 5,60 – – 11,20 11,20 | – 1,60x 32 1,60x 25 1,20x 16 1,20x 16 – – 5 x20 5 x20 |

(3) Materials not mentioned in Table IV shall not be used for anchors unless they are tested, and the local authority is of the opinion that they are equally satisfactory to those mentioned in Table IV:

Provided that the curtain-wall may be fixed to the frame by some other means acceptable to the local authority.

31. PANEL-WALLS.

(1) Panel-walls shall be secured to the structural frame at both ends and, where required by section 52, along their tops, so as to prevent lateral movement, by means of corrosion-resistant anchors, each of cross-sectional area of not less than 60 square millimetres.

(2) There shall be one anchor for each 0,5 square metre or remaining part thereof of the face area of the panel-wall, and anchors shall be evenly spaced along such edges of the wall as are anchored by another approved method.

(3) Panel-walls which overhang their supports shall comply with the requirements of section 22.

32. PARTITION -WALLS.

Every partition-wall shall either be bonded or anchored to cross-walls at both ends as required by section 8 or 19, or shall be so fixed at one end only and at the other be fixed to a framework which, in the opinion of the local authority, provided an adequate lateral support.

33.CAVITY-WALLS : GENERAL.

(1) Cavity-walls may be used for load bearing purposed, subject to the conditions specified in this section.

(2) The inner and outer leaves of the shall be separated by a cavity which shall, throughout, be of a width of not less than 50 and not more than 75 millimetres, and, where the damp-proof layer does not bridge the cavity, shall, throughout extend at least 150 millimetres below damp-proof level, but in no case below finished ground-level.

(3) The inner and outer leaves of the wall shall be securely tied to each other with bonding-ties in accordance with the following paragraphs-

a) such ties shall be placed at distances apart not exceeding 1 metre horizontally and 450 millimetres vertically;

b) within 150 millimetres of the sides of every opening, there shall be one tie to every 300 millimetres of height of such opening if the leaves are not connected by a bonded jamb;

c) the ties shall be butterfly type or vertical twist type, and shall conform to S.A.B.S. 28. Metal ties for cavity walls

(4) During construction, the cavity shall be cleared regularly of mortar droppings or other debris, and provision shall be made to drain the cavity.

(5) The cavity shall be sealed at the top of the wall, and, if the wall in the storey above overhangs the wall beneath, the lower wall shall be sealed at its top by solid walling of a height of not less tha 215 millimetres and of a thickness, measured in the direction of the thickness of the wall, of not less than 215 millimetres.

(6) where the wall supports a floor on which the superimposed load exceeds 250 kilograms per square metre of floor area, the floor-loads shall be deemed to be carried entirely on one leaf of the wall, which shall be designed and constructed to carry such load.

(7) The external leaf of a load-bearing cavity-wall shall be supported by floor-slabs carried through both leaves of the wall at vertical intervals not greater than 12 meters or three Storeys, whichever is the lesser; in such a case, the internal leaf of the wall below such a slab shall be designed to carry the loads coming from both leaves of the wall above such slab.

34. GENERAL REQUIREMENTS FOR HOLLOW MANSONRY UNITS.

Where hollow masonry building-units are used in masonry construction, the following requirements shall be complied with-

a) where roofs, floors or beams bear directly on walls, piers or columns, either-

i) all cavities in the top course of the building -units in the supporting member shall be completely filled with mortar of the same class as that used for laying the units; or

ii) the top course in the supporting member shall be of sold building-units not less than 100 millimetres in height;

b) where a wall of hollow units is decreased in thickness at any particular height, the top course of units of the thicker section shall either be completely filled with mortar of the same class as that used in laying the units or be of solid units not less than 100 millimetres in height;

c) in no case shall a foundation-wall of hollow units be corbelled to carry a thicker wall;

d) in no case shall a wall of hollow units supports a veneer, except in accordance with S.A.B.S. 073;

e) where mortar is spread on the cross-webs, a clear space, free of mortar, not less than 25 millimetres in width, may be left at the centre of each such web to prevent the passage of moisture through the joint.

35. GENERAL REQUIREMENTS FOR SOIL-CEMENT UNITS.

(1)Soil-cement building-units shall not be use in masonry in the following cases-

a) in basement-walls or foundation-walls;

b) in lintels and arches;

c) in walls exposed, in the opinion of the local authority, to prolonged rainfall or continual dampness;

d) in veneered walls.

(2) Soil-cement blocks and soil-cement bricks may be used in bearing-walls other than those set out in subsection (1) if such walls are designed in accordance with the provisions of sections 63 to 82.

(3) In walls not designed in accordance with the provisions of sections 63 to 82-

a) soil-cement blocks may be used only in single-storey and double-storey buildings; and

b) soil-cement bricks may be used only in single-storey buildings.

(4) Two-storey buildings built of soil-cement block shall be strengthened by a concrete-belt course which is-

a) not less than 150 millimetres in depth, and of the full width and length of the walls; and

b) reinforced with two 10 millimetre-diameter mild-steel rods, or reinforcement of equivalent cross-sectional area; and

c) of Grade 20; and

d) situated immediately under the upper-floor joists;

and which shall extend continuously around the building.

(5) Conduits and piped, other than water-pipes, plumbing and drain-pipes, may be housed in chases in soil-cement walls:

Provided that, if such conduits or pipes are of an external diameter greater than 25 millimetres, such chases shall not be cut, but shall be built in as the work proceeds, and the wall shall be thickened around the chase to the extent of the dimensions of the chase.

36. GENERAL REQUIREMENTS FOR GYPSUM BLOCKS.

(1) Gypsum blocks shall be used only in non-loading-bearing, interior walls which are not, in the opinion of the local authority, exposed to continuous dampness.

(2) Gypsum blocks shall not be laid in any mortar other than gypsum mortar, and shall not be allowed to come into contact with Portland cement and Portland cement products within seven days after the cement was mixed with water.

37. GENERAL REQUIREMENTS FOR HOLLOW GLASS BLOCKS.

(1) Hollow glass blocks used in masonry walls shall be regarded as forming non-load bearing panels in such walls, which, for the purposes of section 1 shall be regarded as openings, and shall comply with the requirements of the following subsections.