Chapter 6:

MISCELLANEOUS MATERIALS AND CONSTRUCTION

Arrangement of Sections

Preliminary

Section

1.Intepretation of terms

Part I

DAMP-PROOFING AND WATERPROOFING

2. General requirements for damp-proofing and waterproofing.

3.Detailed requirements

4.Foundation -walls

5.Cavity -walls

6.Openings in external cavity-walls.

7.Parapets and external projections.

8.Floors.

9.Basements.

Part II

ROOFING

10.General

11.Mastic asphalt roofing.

12.Bituminous-felt built-up roof-coverings

13.Asbestos-cement roof slates.

14.Asbestos-cement roof sheeting

15.Asbestos-cement decking-units

16.Galvanized-steel roofing.

17.Aluminium and aluminum -alloy roofing

18.Copper-sheet roofing

19.Slated roofing

20.Concrete roofing tiles.

21.Clay roofing tiles

22.Cut wooden shingles

23.Thatching

24.Glass in roofing

Part III

GLASS IRON AND STEEL IN BUILDING

25.General requirements

26.Minimum nominal thickness of glass for glazing

27. Method of glazing

28. Cast iron in buildings

29.Methods of protection against corrosion.

First Schedule: Water-absorption test on roofing-slate.

PRELIMINERY

1. INTEPRATATION OF TERMS

“back filling” means the material with which a trench or excavation is refilled;

“butt exposure” means the length of a slate, shingle or tile which is exposed below the edge of the next row of units above when laid on the roof;

“corrosion-resistant” means having the ability to resist gradual chemical or electro-chemical change caused by atmosphere, moisture or other agents;

“damp-roof” means having the ability to prevent passage of moisture in the absence of hydrostatic pressure;

“finished ground-level” means the permanent surface of the ground adjoining the building as distinct from the ground-level before commencement of building-operations;

“glazing -bars” means bars made with rebates or of special shapes to support panes of glass in position, and to which the panes may be secured;

“habitable room” means any room designed for human occupation, but excluding bath-rooms, water-closets, stairways, passageways, lift-cars, photographic dark rooms, sculleries, domestic laundries, cold rooms or garages used for parking only;

“roof-pitch” or “roof-slope” means the inclination of a rather or roof to the horizontal measured in degrees of arc;

“safety-glass” means laminated safety-glass, solid heat-treated safety-glass (toughened glass), wired glass or polished wired glass;

“side-lap” or “end-lap” means the distance by which one roofing-unit overlaps the next at its side or end;

“waterproof” means having the ability to prevent the passage of water under hydrostatic head;

“water-table” means the level of the free surface of undisturbed water which will stand in any excavation on the upper limit of the zone of saturation by water in the ground;

“weatherproof” means having the ability to prevent the entry of water into a building under unobstructed conditions of runoff.

2. GENERAL REQUIREMENTS FOR DAMP-PROOFING AND WATERPROOFING

The following requirements apply regarding damp-proofing and waterproofing-

a) subject to the provisions of paragraph (c), there shall be provided, in the erection of every building, damp-proofing or water-proofing, in accordance with the requirements of this Chapter;

b) water or moisture shall be prevented from entering the interior of such building, except as provided for in subsection (6) of section 9;

c) the local authority may permit the omission of damp-proofing or water proofing in any building in which there are no habitable rooms, and where the person intending to erect such building can show to the satisfaction of the local authority that no danger to the health of persons or to the stability of the building will be caused by the entry of moisture or water into the building;

d) damp-proofing and waterproofing materials shall comply with C.A.S. No A25. Damp-proofing materials, or be other material approved by the local authority;

e) mastic asphalt damp-proof courses shall be applied in at least two layers.

f) damp-proofing and water proofing procedures following S.A.B.S. O21, waterproofing of buildings, shall be deemed to satisfy the requirements of this section.

3. DETAILED REQUIREMENTS

(1) Horizontal damp-proof courses.-Every horizontal damp-proof course shall be constructed to the full width of the wall resting upon it, and shall also extend full width of any wall-plate which may rest upon the damp-proof course.

(2) For the purpose of this section, a cavity-wall shall be regarded as two separate walls.

(3) Where composed of sheeting, horizontal damp-proof courses shall be lapped not less than 100 millimeters at the joints.

(4)Vertical damp-proof courses.-If in any solid wall the horizontal damp-proof course is not situated at least 150 millimeters above the finished ground-level, a vertical damp-proof course (or water course if required) shall be taken up the outer face of the wall from the horizontal damp-proof course to at least 150 millimetres above the external-finished ground-level, and there finished off in such a manner as to prevent the entry of moisture; and shall be protected by brick-work of not less than 65 millimetres in thickness, or by such other method as may be approved by the local authority.

4. CAVITY-WALLS

In cavity-walls, damp-proof courses shall be provided in such a manner as to-

prevent moisture from the soil or foundation-walls from rising into the wall above the level of the ground-floor or reaching any timber in the floors; and

a) allow any moisture from the cavity to drain outwards through weepholes or open vertical joints left at intervals in the outer leaf of such walls.

5. CAVITY -WALLS

In cavity-walls, damp-proof courses shall be provided in such a manner as to-

prevent moisture from the soil or foundation-walls from rising into the wall above the level of the ground-floor or reaching any timber in the floors; and

a) allow any moisture from the cavity to drain outwards through weep-holes or open vertical joints left at intervals in the outer leaf of such walls.

6. OPENINGS IN EXTERNAL CAVITY -WALLS

In external cavity-walls, damp-proof courses shall be provided at sills and heads of all openings, to prevent the passage of moisture from the outer to the inner leaves of the wall.

7. PARAPETS AND EXTERNAL PROJECTIONS

Damp-proof courses shall be provided to parapets and, where required by the local authority, to external projections in such manner as to prevent the passage of moisture into the building.

8. FLOORS

(1) General.-Solid floors in contact with the ground shall be a minimum thickness of 75 millimeters and shall be so constructed or treated as to render them damp-proof.

(2) Where required by the local authority, a horizontal damp-proof course shall be laid under the floor for its full extent.

(3) Washroom and toilet-room floors. – The floors of washrooms and toilet-rooms shall be of tile, terrazzo, granolithic and other impervious material, and have a skirting of impervious material of not less than 75 millimeters in height around the walls.

9. BASEMENTS

(1) Floors.-Basement-floors shall be-

a) damp-proof; and

b) where ground-water is present or is likely to rise above such floor -level and is to be drained away from the building, the floor shall be laid on a layer, of not less than 100 millimeters in thickness, of broken stone, rubble or other fragmented material, the underside of which layer shall be above the top of the footing of any wall or column.

(2) Walls.- Basements-walls shall be provided with vertical damp-proof courses where damp-proof courses are required by section 2, and shall be in accordance with the provisions of section (4) of section 3.

(3) Where ground-water is present or is likely to rise above basement-floor level and is to be drained away from the building, a layer of fragmented material of not less than 75 millimeters in horizontal thickness shall be placed between the walls and any back-filing. Such layer shall-

a) communicate with the layer of similar material under the floor; and

b) extend to a level of 150 millimeters above the highest level of the water-table.

(4) Junction of floor and wall.-The junction between basement-floors and walls and columns shall be rendered damp-proof, unless, in the case of internal walls and columns, the floor itself has been rendered damp-proof or waterproof.

(5) Disposal of ground-water.-Where ground-water is present or is likely to rise above the basement-floor level and such water is to be prevented from entering the building-

a) means shall be provided by gravity or by pumping effectively to drain the water from the fragmented material around the walls and from under the floor of the basement; or

b) the basement shall be made waterproof to a level of at least 150 millimeter’s above the highest level of the water-table at the site.

(6) Where water is to be allowed to enter any building, weep-holes shall be made in the lowest floor or in the walls as such floor-level, and the water led by channels to a sump from where it shall be pumped away to a discharge-point indicated by the local authority.

10. GENERAL

(1) Roof-coverings.- All roofs and roof projections of buildings shall be weatherproofed and shall be covered with one or more of the coverings detailed in this Part.

(2) The coverings shall be secured so as withstand climatic conditions, such as wind pressure, wind suction and changes in temperature.

(3) Notwithstanding the restrictions placed on the profiles and sizes of roof coverings in sections 13 to 21 and the B.S., S.A.B.S. and C.A.S. mentioned therein, alternative profiles and sizes of the respective materials may be used, if approved by the local authority.

(4) Substructure.- The trusses, rafters, purlins or other supporting framework to roof-coverings shall be designed in accordance with the respective requirements for concrete, steel or timber, contained in these by-laws.

(5) Timber battens and purlins shall be provided of such strength, dimensions and spacing as shall adequately support the roof covering applied to them, together with all superimposed and wind loads, to the satisfaction of the local authority.

(6) Roofs with more than one kind of covering.-Where a roof-covering is provided over another roof-covering, the minimum roof-pitch shall be taken as the minimum pitch allowable.

(7) Flashing.-Flashing shall be provided so valley and the junction of roofs with chimneys, parapets and other abutting surfaces, so as to render the roof weatherproof, and such flashings shall comply with the following requirements-

a) they shall be corrosion-resistant;

b) they shall be composed of soft copper, zinc, aluminum, hard lead, galvanized metal, asbestos-cement or other approved material having similar corrosion-resistant qualities. Zinc flashings shall have a mass of not less than 4 kilograms per square meter, and lead flashings of not less than 15 kilograms per square meter. The minimum thickness for flashings of copper, galvanized metal or aluminum shall be 0,55 millimeter. Asbestos cement flashings shall be at least 5 millimetres in thickness;

c) whenever a metal flashing or other metal fitting is used in conjunction with a dissimilar metal, whether of the roof or another fitting, which may lead to electrolytic corrosion between them, provision shall be made to prevent such corrosion by painting on contacting surfaces wit bitumen-based paint or by any other method which will prevent a galvanic couple being formed;

d) flashings to the junction of roofs with chimneys, parapets and other abutting surfaces shall be in two pieces. The underneath flashing shall extend at least 100 millimeters up vertical surfaces and shall be covered with the second flashing which shall be securely wedged and pointed.

11. MASTIC ASPHALT ROOFING

The mastic asphalt used for roofing shall comply with the requirements of C.A.S. No. A1, Mastic asphalt for roofing (limestone aggregate), or shall otherwise be to the satisfaction of the local authority.

12. BITUMINOUS-FELT BUILT UP ROOF-COVERINGS

Bituminous-felt built-up roof coverings shall comply with the following requirements-

a) the exposed layer or layers shall comply with the requirements of C.A.S. NO. A30, Bitumen roofing felt surfaced with natural mineral granules of slate or stone rolled into the surface during manufacture in such a manner as to form a closely compacted surface;

b) unexposed layers shall be of mineral-stabilized asphaltic roofing felt or asphalt-saturated felt;

c) such coverings shall be laid on a continuous deck of tounge-and-groove wrought timber boarding or concrete or other approved material, with a minimum fall of 1 in 70 towards rainwater outlets;

d) when the slope of a roof exceed 1 in 4, the built-up roof covering shall be fixed to the deck.

13. ASBESTOS-CEMENT ROOF -SLATES

(1) Asbestos-cement slates shall comply with the requirements of B.S. 690 or C.A.S. 198.

(2) Slates shall be laid so that the following requirements are met-

a) each course shall overlap the second course below it by not less than-

(i) for a diamond or honeycomb pattern, 75 millimeters ; and

(ii) for rectangular pattern, 100 millimeters;

b) for diamond or honeycomb-pattern slates, the roof-slope shall be not less than 25 degrees;

c) for rectangular-pattern slates, the roof slopes shall be not less than 17 ½ degrees;

d) where additional weatherproofing is provided to the satisfaction of the local authority, the roof-slopes referred to in paragraphs (b) and (c) may be reduced.

14. ASBESTOS-CEMENT ROOF -SHEETING

(1) Asbestos-cement corrugated sheets for roofing shall comply with requirements of C.A.S. 198 or B.S. 690, and asbestos-cements ridging , barge-boards , flashings and other accessories shall be of material of similar quality and thickness

(2) Except as provided for in subsection (3), where asbestos-cement roof-sheeting is used on a roof, the roof shape shall be not less than 10 degrees, and the minimum side-laps and end-laps shall be in accordance with Table 1.

TABLE 1

MINIMUM SIDE-LAPS AND END-LAPS FOR ASBESTOS-CEMENT ROOF-SHEETING

| 1 | 2 | 3 |

| Roof slope degrees | Side lap in millimeters | End lap in millimeters. |

| More than 17 More than 124, but not more than 17. Not more than 124 | 45 45 45 | 150 225 225 300 |

(3) Where asbestos-cement roof-sheeting is used on a roof and the roof-slope is less than 10 degrees, both side-laps and end-laps must be sealed with a non-hardening compound.

15. ASBESTOS- CEMENT DECKING UNITS.

(1) Asbestos-cement decking-units shall comply with the requirements of B.S. 3717.

(2) Asbestos cement decking units shall be laid and fixed to the satisfaction of the local authority.

16. GALVANISED -STEEL ROOFING

GALVANIZED-STEEL ROOFING’ 16. (I) General. —Galvanized -steel roofing shall be not less than 0,55millimetre in Mc and the coating shall with the requirements of the S.A.B.S. 934, Hot-dip (galvanized) zinc coated steel sheet and strip.

(2) Corrugated galvanized-steel roofing. —C gated galvanized-steel roofing shall comply following requirements—

(a) except as provided for in paragraph roof-slope shall be not less than 12 – and the minimum side-laps and end laps the sheets shall be in accordance with Table II

TABLE II

MINIMUM SIDE-LAPS AND END-LAPS FOL CORRUGATED GALVANIZED-STEEL SHEET! ON ROOFS

| 1 | 2 | 3 |

| Roof-slope, in degrees | Side-lap | End lap in millimeters. |

| More than 25 More than 20, but not more than 5. Not less than, t not more than. . | 1.5 corrugations 1.5 corrugations 1.5 corrugations | 150 250 300 |

(b) where additional weatherproofing, such as the use of an underfelt timber boarding or caulking of the joints, or other method approved by the local authority, is provided, the slope of the roof may be less than 12,5 degrees, and the slope in that case shall be not less than 7 degrees.

Flat galvanized-steel roofing shall be laid on a deck complying with the requirements of paragraph (c) of section 12, except that timber decks may be unwrought and butt-jointed.

(4) Galvanized-steel fluted (inverted box-rib). roofing. —Galvanized-steel fluted roofing shall comply with the following requirements—

(a) the roof-slope shall be not less than I degree with the sheets seam-bolted together at all side-laps with galvanized scam-bolts of not less than 6 millimeters diameter and the mini-mum side-laps and end-laps of sheets and the maximum seam bolting centers shall be in accordance with Table III;

TABLE III MINIMUM SIDE-LAPS AND END-LAPS AND MAXIMUM SPACING OF SEAM-BOLTS FOR GALVANIZED-STEEL FLUTED SHEETS ON ROOFS

| 1 | 2 | 3 | 4 |

| Roof slope In Degrees | Side lap ribs | End Lap in Millimeters | Maximum spacing of seam-bolts, in millimeters. |

| -More than 25 -More than 20 but not more than 25 -More than 15 but not more than 20 -More than 7 but not more than 15 -Not less than 5 but not more than 7 | 1 1 1 1 1 1 | 150 180 200 230 250 300 | 600 525 450 400 350 300 |

Sheets laid at a slope of less than 5 degrees shall have end laps sealed with an approved sealing compound.

17. ALUMINIUM AND ALUMINIUM-ALLOY ROOFING

(1) General.- Aluminum and aluminum-alloy roofing shall be protected from any dissimilar metal, and from concrete or mortar on which it may rest, by a layer of suitable bitumen-based or coal-tar pitch-based paint between the contact surfaces or by an insulating material approved by the local authority.

(2) Corrugated-aluminum roofing. – Corrugated-aluminum-alloy roofing shall comply with the following requirements-

a) where the corrugation pitch is between 65 millimeters and 80 millimeters and the depth of corrugation is 19 millimeters ± 1 millimeters, the thickness of sheet shall be not less 0,7 millimeter, and the maximum purlin spacing, measured center to center, shall be 1,2 meters for the 0,7-millimeter sheet.

b) the requirements for laps and minimum slope shall be as set out in paragraphs (a) and (b) of subsection (2) of section 16 for corrugated-steel sheets.

(3) Aluminum flat-sheet roofing laid in a deck. – Where aluminum or aluminum-alloy roofing in the form of a flat sheets is laid on a deck, the following requirements shall be met-

a) where the roofing is a single-layer weather-proof covering, the minimum thickness of sheet shall be 0,5 millimeter.

b) the deck shall be continuous and shall comply with the requirements of paragraph (c) of section 12, except that timber may be unwrought and butt-joints.

(4) Aluminum-foil built-up roof coverings. – Where aluminum foil is used for built-up roof-coverings on a continuous concrete or boarded deck, the following requirements shall be met-

a) where such a foil is used as a single-layer covering for a bituminous-felt built-up roof-covering, or where such foil is used in a built-up roof-covering of successive layers, the thickness of foil shall be not less than 0,05 millimeter and not more than 0,1 millimeter.

b) where such foil is used as a single layer covering over concrete roofs or over bituminous felt on a boarded deck the thickness of foil shall be not less than 0,08 millimeter and not more than 0,1 millimeter.

c) the foil shall be embossed to ensure good adhesion and to allow for expansion.

d) the deck shall comply with the requirements of paragraph (c) of section 12, or be a shell-type concrete roof, steel-rowelled to a smooth finish after having attained its initial set.

e) when laid on a flat deck without bituminous felt, a minimum of two thickness of foil shall be laid in shingle pattern, with use of an approved grade of hot bitumen or cold adhesive.

f) when foil is laid on shell-type roofs, an approved cold adhesive shall be used. If only a single thickness of foil is required, there shall be a lap of at least 100 millimeters at any joint.

(5) Aluminum fluted-sheet roofing (long-span custom).- Aluminum fluted-sheet roofing shall comply with the following requirements-

a) the roof-slope shall be not less than 3 degrees with the sheets seam-bolted together at all side-laps with aluminum seam-bolts of not less than 6 millimeters diameter, and the minimum side-laps and end-laps of sheets and the maximum seam-bolting centers shall be in accordance with Table IV;

TABLE IV

MINIMUM SIDE-LAPS AND END-LAPS AND MAXIMUM SPACING OF SEAM-BOLTS FOR ALUMINIUM FLUTED SHEETS ON ROOFS

| 1 | 2 | 3 | 4 |

| Roof-slope, in degrees | Side-lap | End lap in millimeters. | Maximum spacing of seam-bolts, in millimeters. |

| -More than 15 | 1.5 | 150 | 600 |

| -Not less than 10, but not more than 15. | 1.5 | 250 | 450 |

| -Not less than 3 but less than 10 | 1.5 | 380 | 300 |

b) where the roof-slope is less than 10 degrees, the end-lap shall be sealed with an approved mastic sealer

18. COPPER-SHEET ROOFING

(1) General.- Copper sheets for roofing, including clips, shall be not less than 0,55 millimetres in thickness, and shall be made from hot rolled-sheet of dead-soft temper.

(2) Detailed requirements.- Copper sheets for roofing shall be laid on a deck complying with the requirements of paragraph (c) of section 12, except that timber decks may be unwrought and butt joined.

19. SLANTED ROOFING

(1) Roof-slates shall be of impermeable fine-grained rock, free from knots and knurls, and of such nature and so located that the durability or weatherproofing of the roof is not adversely affected thereby.

(2) Roof-slates shall, in addition, meet the following general requirements-

a) every slate shall be of uniform thickness throughout, which shall be not less than-

(i) 5 millimetres for all sizes not larger than 300 x 250 millimetres;

(ii) 6 millimetres for all sizes larger than 300 x 250 milimetres;

b) slates shall have a water absorption not exceeding 0,8 per centum of their dry mass, when subjected to the test set out in the First Schedule;

c) the width of each slate shall be at least half its length;

d) for slates laid on open battens, the roof slope shall be not less than 30 degrees, except as provided for in paragraph (e), and the sizes of slate used shall comply with those given in Table V for the appropriate roof-slope;

TABLE V

SIZES OF SLATES FOR VARIOUS ROOF-SLOPE.

| 1 | 2 | 3 |

| Sizes of Slate in millimeters | ||

| Roof-slope, in degrees Sizes | Length | Minimum Width |

| More than 40 . | 250 – 300 | 150 |

| 360-400 | 200 | |

| 450-500 | 250 | |

| 500 | 300 | |

| More than 35 but not more than 40 | 250-300-360-400 | 200 |

| 450-500 | 250 | |

| 560 | 300 | |

| Not less than 20 but not more than 35 | 250-300 | 200 |

| 360-400-450-500 | 250 | |

| 560 | 300 |

e) where additional weatherproofing to the satisfaction of the local authority, the roof-slope may be less than 30 degrees, and in that case shall be not less than 20 degrees.

20. CONCRETE ROOFING TILES

(1) Materials. —Concrete roofing tiles comply with the requirements of C.A.S. 187, concrete roofing tiles. (2) Detailed requirements. —The following terms shall be met in regard to the laying firing of concrete roofing tiles on the roof—(a) except as provided for in paragraph the roof-slope shall be not less than—

| Side lap | End lap | Minimum Slope |

| 25 mm | 75 mm | 26.5 |

| 38 mm | 108 mm | 17.5 |

a) Where additional weatherproofing, sue the use of an underfelt or a sheet-metal or other method approved by the authority, is *ded, the roof-slope be less tha 171 e s, and in that shall be not I grees. If an felt is used on board the battens sht mounted on counter-battens, to e drainage.

21. CLAY ROOFING TILES

(1) Marseilles-pattern and plain-clay roofing tiles shall comply with the requirements of S.A.B.S. 623, Clay roofing tiles.

(2) Clay roofing tiles, other than Marseilles-pattern and plain tiles, shall be made accurate to their nominal dimensions with the following tolerances-

a. thickness: 2 millimetres(for plain tiles tiles only);

b. breadth: ±3 per centum of nominal breadth;

c. length: ± 3 per centum of nominal length.

(3) Detailed requirements.- The detailed requirements for clay roofing tiles shall be in accordance with the provisions of subsection (2) of section 20.

22. CUT WOODEN SHINGLES 2.

(1) Impregnation and moisture content.- Cut wooden shingles shall be impregnated in accordance with the requirements in accordance with the requirements of S.A.B.S. 448, South African wood shingles for roofs and walls, and shall also conform to the moisture-content clause of that specification.

(2) General requirements.- Cut wooden shingles shall comply with the following requirements-

a. shingles shall taper from butt to tip and shall be made to the following requirements-

(i) the nominal lengths of shingles shall be not less than 400 millimetres;

(ii) the widths of shingles shall be any random width from 100 millimetres to 200 millimetres;

b) the maximum permissible butt exposure shall vary with the roof slope, in accordance with Table VI;

c) values of maximum permissible butt exposure for roof-slopes between 26 and 34 degrees, and for shingles of different length from that specified in paragraph (a), shall be obtained by linear interpolation;

d) in no case shall the roof-slope be less than 20 degrees.

TABLE VI

BUTT EXPOSURE FOR CUT WOODEN SHINGLES

| 1 | 2 |

| Roof slope from the horizontal in degrees | Maximum permissible butt exposure in millimeters |

| More than 34 Not less than 26, but not more 34 than Not less than 20, but less than 26. | 125 95 95 (plus an undercoat of roofing felt laid on boarding) |

23. THATCHING

The following requirements apply in regard to thatching-

a) the thickness of the thatching shall be not less than 130 millimetres at any part of the roof, and shall consist of not less than two layers of bundles of thatching;

b) at eaves the verges, there shall be layer of bundles of thatching additional to those required in paragraph (a);

c) at valleys, hips and ridges, approved soakers shall be provided which shall be covered with a layer of bundles of thatching additional to those required by paragraph (a), and the total thickness shall be not less than 200 millimetres;

d) except as provided for in paragraph(e), the slope of the roof shall be not less than 45 degrees;

e) when a thickness of thatching double that required under paragraph (a) is provided, the slope of the roof may be reduced to 35 degrees.

24. GLASS IN ROOFING 3

1 General.- Where glass is employed as a roofing-material or in vertical glazing or louvres at a height of more than 3,5 meters above the level of the interior floor concerned, the glass shall be of one of the types listed in Table VII, and shall comply with the requirements for that type.

TABLE VII

APPROVED GLASSES FOR USE IN ROOFS AND HIGH VERTICAL GLAZES

| Types of Glass | Minimal nominal thickness in millimeters | Other requirements |

| Wired Solid heat-treated safety-glass (toughened glass). Glass tiles Rough-cast domes Thick rough-cast and polished (plate). Laminated safety- glass Sandwich safety-glass | 6 6 6 9 10 6 6 | Wholly bonded with an inter-layer not subject to deterioration with age. Securely bonded along the entire length of all the edges with materials not subject to deterioration with age. |

(2) Notwithstanding the provisions of subsection (1), sheet glass may be used in vertical glazing where the area of any one pane does not exceed 0,25 square metre and is supported on all sides and, where louvres form a part of the vertical glazing, the nominal thickness of sheet glass in the louvres shall be not less than 5,5 millimetres.

(3) Width of flat glass in roofing.-The maximum permissible width of all types of flat glass referred to in Table VII, shall be 600 millimetres, and such glass shall be supported at least along both long edges.

(4) Roof-slopes.- The minimum roof-slope for glass roofing on a uniform pitch shall be 20 degrees, except in the case of glass tiles, which shall have the same slope as laid in section 21 for clay roofing-tiles of the same type.

(5) Glazing-bars.- Glazing-bars shall conform to the requirements of one of the following paragraphs –

a) they shall be constructed in accordance with one of the following subparagraphs, being made of-

(i) a steel section sealed with integrally extruded lead sheath-covering (the mass of lead shall be not less than 10 kilograms per square metre, giving a minimum thickness of 1 millimetre);

(ii) a galvanized-steel bar, the zinc coating of which shall be not less than 600 grams per square metre with a capping of non ferrous metal;

(iii) a composite bar consisting of a timber supporting bar with a non ferrous metal section on top to receive the glass, and with a capping of similar metal;

(iv) a reinforced-concrete bar, with approved capping;

(v) a bar of aluminium alloy, with a capping or weathering-wings of aluminium or lead;

or

b) they shall be made of, or sheathed with, corrosion-resistant material, to the satisfaction of the local authority.

2 See the requirements of Chapter 11 for restrictions on the use of this type of roofing

3See section 27 for the method of glazing to be used.

25. GENERAL REQUIREMENTS

Glass for glazing shall be of the type mentioned, and of the minimum nominal thickness and mass per square metre shown against each individual type in section 26.

26. MINIMUM NOMINAL THICKNESS OF GLASS FOR GLAZING

(1) Subject to the provisions of subsection (1) of section 24 and to provisions of subsections (3), (4) and (6), the minimum nominal thickness and masses per square metre of glass for vertical glazing in buildings, other than roofs, shall be as set out in Table VIII for each type of glass shown.

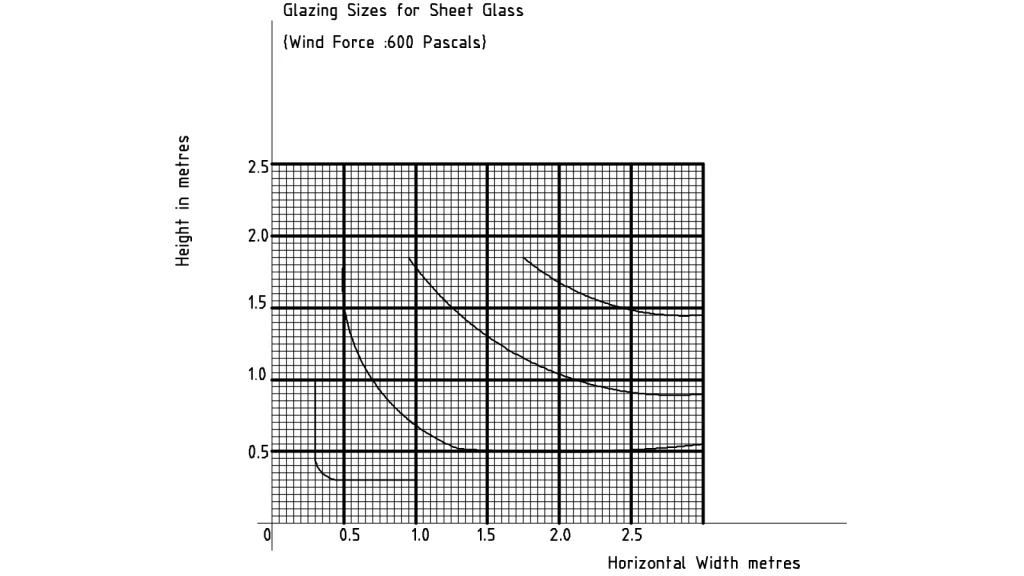

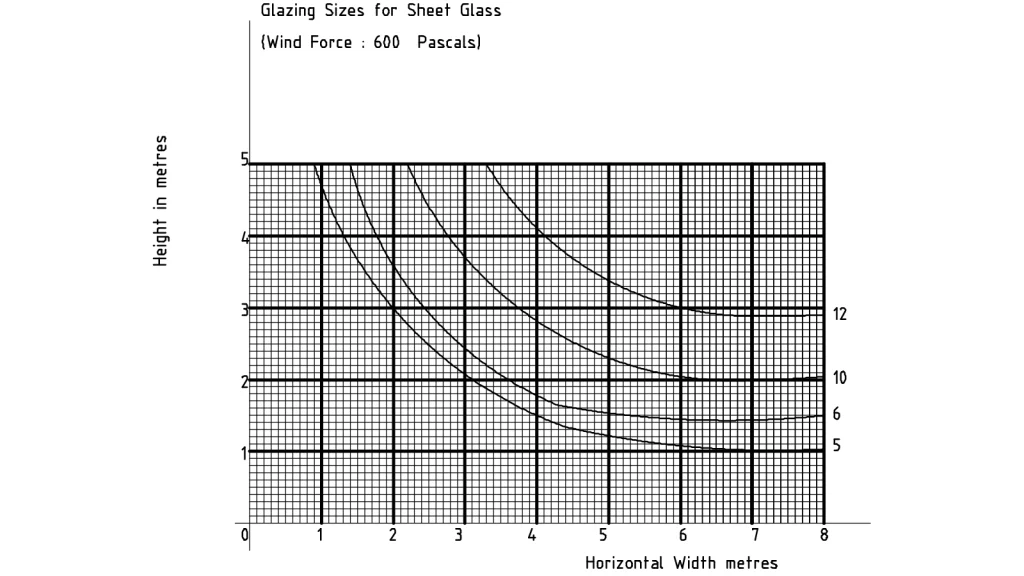

(2) The maximum glazing-sizes for the corresponding masses per square metre and nominal thickness of sheet glass and polished plate glass shall be determined by reference to the Second Schedule and Figures 1 and 2 in the Schedule, and these sizes shall not be exceeded except where the opening to be glazed is nowhere more than 3,5 metres above the level interior floor concerned,

| 1 | 2 | 3 |

| Type of glass | ||

| Polished plate. | 6 | 15 |

| Float | 6 | 15 |

| Sheet | 2 | 5 |

| Cathedral, and figured and rolled | 3 | 7,5 |

| Plain rolled | 3 | 7,5 |

| Rough-cast | 5 | 12,5 |

| Wired | 6 | 15 |

| Polished wired. | 6 | 15 |

| Prismatic | 6 | 15 |

| Heat-absorbing | 6 | 15 |

| Solid heat-treated safety-glass (toughened glass) | 5 | 12,5 |

| Laminated. | 6 | 14 |

| Sandwich | 6 | 15 |

when the width may be increased by 20 per centum.

(3) Where glass is used in doors, in panes framed on all edges and larger than 0,5 square metre in area, it shall be safety-glass of a thickness to the approval of the local authority for the size of pane concerned.

(4) where glass doors are unframed, they shall be of safety-glass of thickness to the approval of the local authority.

(5) Where transparent glass is used in doors, either framed or unframed or in vertical glazing situated between floor-level and a height of 2 metres above floor level, and, in opinion of the local authority, the presence of the glass may not be apparent to, or suspected by, a person approaching it, the glass shall bear markings which render the glass clearly apparent, except that, where a close approach to the glass is prevented by barrier-wails or other approved means of preventing an accidental collision with the glass, such markings shall not be required.

(6) Any glass louvre, wherever situated, unless supported on both edges shall have a minimum thickness of millimetres and shall have both edges ground smooth.

27. METHOD OF GLAZING

Glazing shall be carried out with such materials as will ensure the glass is securely held in surrounding frames or openings and is capable of resting wind pressure and rain penetration, and will not be dislodged by normal movement of frames designed to move to which the glass is fitted.

28. CAST IRON IN BUILDINGS

(1) Material specification.- Cast iron used for structural members in buildings shall be of grade not less than Grade 10 of B.S. 1452.

(2) Permissible stresses.- The permissible stresses in cast-iron structural members shall not exceed the values given below in megapascals-

Tension in bending 21

Axial tension 21

Shear 14

Axial compression (bearing) 83

Compression in bending 42

Compression in columns 83-28 l/r where l/r, the slenderness ration, is the ration of the actual length of the member to the least radius of gyration of its cross section.

(3) If a cast-iron column is not symmetrical about both longitudinal axes, and is not supported laterally between its ends, its slenderness ration shall be determined by the methods detailed in appropriate standard in Chapter 3.

(4) Columns and compression-members.- No cast-iron column or other cast-iron compression-member shall have a length, l, exceeding 100 times its least radius of gyration, r.

(5) The ends of all cast-iron columns shall be fixed in position and direction.

29. METHODS OF PROTECTION AGAINST CORROSION

All iron and steel structures used in building shall be coated to comply with the following codes of practice-

| IRON B.S. CP 2008 | Protection of iron and steel structures from corrosion |

| STEEL B.S. CP 2008 | Protection of iron and steel structures from corrosion, and |

| B.S. 3189 | Phosphate treatment of iron and steel. |

FIRST SCHEDULE (Section 19)

WATER-ABSORPTION TEST ON ROOFING-SLATE

PREPARATION OF TEST SPECIMENS

1. For each test, take at random three slates from the material to be tested, and from each slate prepare a specimen measuring 50 x 50 millimeters x the thickness of the slate. Cut the specimens with a suit-able tool and take care to avoid cracking or splintering the slate. Grind all the edges with water and a fine abrasive to give a smooth finish. Do not use specimens having cracks or other defects caused during their preparation.

WATER-ABSORPTION TEST 2. Dry the three test specimens to constant weight in an oven at 105 degrees Celsius over a period of about 48 hours, and then submerge the specimens in distilled water in a suitable receptacle provided with a reflux condenser and boil gently and continuously for 48 hours. After cooling in air for five minutes, place the specimens in cold water and allow them to stand for 30 minutes in the room in which they are to be weighed. Remove the surplus water by shaking,

FIRST SCHEDULE (Section 19)

WATER-ABSORPTION TEST ON ROOFING-SLATE

PREPARATION OF TEST SPECIMENS

1. For each test, take at random three slates from the material to be tested, and from each slate prepare a specimen measuring 50 x 50 millimeters x the thickness of the slate. Cut the specimens with a suit-able tool and take care to avoid cracking or splintering the slate. Grind all the edges with water and a fine abrasive to give a smooth finish. Do not use specimens having cracks or other defects caused during their preparation.

WATER-ABSORPTION TEST

2. Dry the three test specimens to constant weight in an oven at 105 degrees Celsius over a period of about 48 hours, and then submerge the specimens in distilled water in a suitable receptacle provided with a reflux condenser and boil gently and continuously for 48 hours. After cooling in air for five minutes, place the specimens in cold water and allow them to stand for 30 minutes in the room in which they are to be weighed. Remove the surplus water by shaking,

wipe with a damp cloth and immediately weigh the specimens to the nearest 0,001 gram. Calculate the increase in mass of each specimen as the difference between the mass before and after boiling as a per-centage of its dry mass. Take the average of the three values so obtained as the water absorption. If the range of the three values is greater than 10 per centum of the average (indicating that defects may have been caused in preparing the specimens), repeat the test using three further specimens. Take the average of the three new values so obtained as the water absorption of the slate.

SECOND SCHEDULE (Section 26)

GLAZING-SIZES AND THICKNESSES FOR SHEET GLASS AND PLATE GLASS

SHEET GLASS I.

The height and width of any square or rectangular-lar piece of sheet glass shall be not greater than those given by a point lying on the curve m Figure I. corresponding to the nominal thickness of the glass concerned. Examples (dimensions in millimeters)— 2-millimetre glass: 375 x 375; or 1 000 high x 300; or 325 high x 500; 3-millimetre glass: 800 x 800; or I 200 high x 600; or 400 high x 2 500; 4-millimetre glass: 1300 x 1 300; or I 700 high x 1000; or 90D high x 2 500; 5-millimetre glass: I 800 x 1 800; or I 600 high x 2 CCO; or 1 500 high x 2 300. The maximum permissible diameter of a circular piece of sheet glass is as follows—For nominal thickness of-2 millimeters, 500; 3 millimeters, 900; 4 millimeters, 1 450; 5 millimeters, 2 300.

PLATE GLASS 2.

The height and width of any square or rectangular-lar piece of plate glass shall be not greater than those given by a point lying on the curve in Figure 2, corresponding to the thickness of the glass concerned.

Examples (dimensions in millimeters)-5-millimetre glass: 1 600 x 1600: or 2 400 high x 1 200; or 900 high x 7 000; 6-millimetre glass: 2 200 x 2 200; or 4 000 high x 1 400; or 1 300 high x MO: 10-millimetre glass: 3 100 x 3 100; or 4 800 high x 2 KO; or 2 100 high x 6000; 12-millimetre glass: 4 000 x 4 000; or 4 600 high x 3 600; or 2 900 high x 7 ooa The maximum permissible diameter of a circular piece of clear plate glass is as follows—For nominal thickness of-5 millimeters, 1 900; 6 millimeters, 2400; 10 millimeters. 3 600; 12 millimeters, 4600.